Plastic Fuel tank

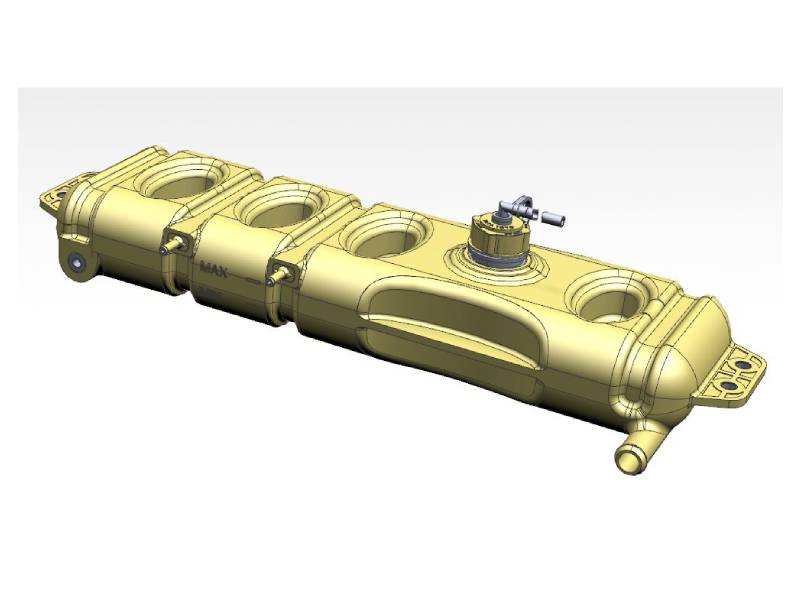

Expansion Tank

Typically found in SUVs and trucks, the centre bearing connects the front and rear driveshafts. A well-designed bearing with have good cushion and ensures minimal noise, vibration, and harshness white the drive train is in operation. Center bearing supports carry the load of the driveshaft and allow for axial and radial deflection at vehicle start-up, when accelerating from a complete stop, and while braking. They isolate the noise and vibration by dampening the resonance that results from shaft-tumbling and is carried to the vehicle cabin via its structure.

Like all our NVH solutions, the center support bearings we manufacture are of high quality. We have our own rubber lab testing facilities for dampers and can conduct centre bearing rubber housing tests for propeller shaft dampers. We utilize our 25 years of experience in every project and work without customers to deliver a solution that works for their specific needs.

PRODUCT

Applications

We have worked with some of the worlds leading OEMs and automobile manufacturers since 1986. Premier Seals has been certified as ISO/TS 16949:2009 by DNV since 2010. We manufacture high-quality center support bearings and work with our customers through the entire development line. Our moto is to deliver high-quality world-class products to clients and ensure the highest level of customer satisfaction.

Our centre bearing rubber components have applications in various industries for light as well as commercial vehicles. This component performs a key role in the safe operation of a vehicle and in keeping NVH to a minimum. Contact us to learn more about our damper products.

Automotive

Automotive

Construction & Mining Equipment

Construction & Mining Equipment

Railway

Railway

Agriculture

Agriculture

Marine

Marine

Engine/Genset

Engine/Genset

PRODUCT

EXPLORE RELATED PRODUCTS

Coolant Tank

Plastic Fuel tank Typically found in SUVs and trucks, the centre bearing connects the front and rear driveshafts. A well-designed bearing with have good cushion ...

Explore Product →

Disel Tank

Plastic Fuel tank Typically found in SUVs and trucks, the centre bearing connects the front and rear driveshafts. A well-designed bearing with have good cushion ...

Explore Product →

Hydraulic Tank

Plastic Fuel tank Typically found in SUVs and trucks, the centre bearing connects the front and rear driveshafts. A well-designed bearing with have good cushion ...

Explore Product →

GET IN TOUCH

WE ARE HAPPY TO HELP YOU!

learn more

CENTRE BEARINGS

WHAT ARE CENTER SUPPORT BEARINGS?

A center support bearing is an NVH isolating and damping component for the power train. It carries the load of the driveshaft and accommodates axial and radial deflection that takes place when a starts-up and while braking. An effective solution to isolate and damp the noise and vibration that is transferred to the vehicle’s structure by the tumbling of the drive shaft. The component includes a rubber compound that is developed for acoustic isolation. This rubber compound is resistant to high temperatures and is able to withstand continuous rotational forces. The rubber is bonded to metal to create the centre bearing. Premier seals is a reputed manufacturer of rubber bonded to metal items. Along with centre bearing rubber we also manufacture other components like anti-vibration mounts, TVDs, flexible couplings, and more. Contact us to learn more about our product catalog.

WHY THE RIGHT COMPONENTS ARE IMPORTANT

Noise, vibration, and harshness play a key role in how the quality of a vehicle is perceived. It is not about eliminating all noise and vibration but about optimizing what noise and vibrations users feel. The components used in the power train have a direct impact on the NVH performance of a vehicle. Automotive manufacturers must ensure they select the right components for their vehicles. The use of components with internal damping properties is increasing. In this highly competitive sector, even small advantages in performance can have a big impact on sales and perception. At Premier Seals we work with our clients from the design stage to ensure the highest levels of performance and quality. We provide recommendations and improvements before the design freeze, before moving to development and manufacture.