OUR

TECHNOLOGY

- We partner with our customers along the entire product life cycle

- We support & provide innovative solutions for all current future mobility challenges for our customers

- We are committed to our best reach, cost and delivery

- We support & provide innovative solutions for all current future mobility challenges for our customers

- We are committed to our best reach, cost and delivery

Core USP

- Packaging in the vehicle environment

- Component level simulation and support at vehicle level validation

- Complete solution from system level calculations to product design to vehicle validations

- Robust PPAP with high quality standard and support to SOP

- Attending field complaints and resolution with 7 step quality control stories and stringent incidence per thousand vehicle (IPTV) targets

- Support in achieving initial quality survey (IQS) and customer satisfaction index (CSI)

- Creating quality index brochure (QIB) and customer issue brochure (CIB)

TECHNOLOGY

Expertise

At Premier Group, We believe in achieving great things. One such hub ERIC is pushing us towards innovation. At the department of ERIC you can see the new now. We have a level of freedom that allows us to focus on our customers, and to combine the best from different worlds in order to develop practical solutions – a unique mixture of technological expertise, material expertise, system calculation, system simulation, advanced engineering, future mobility and a hands-on mentality.

- To foster innovation, collaboration & development across disciplines

- To connect engineering and manufacturing research

- To inspire a new generation of Premier engineers

- To showcase forward thinking Premier engineering and design

Recent Trends & Technology

Product Development Trends

01

POWERTRAIN MOUNT DESIGN FOR NVH

02

TORSIONAL DAMPER DESIGN FOR NVH

03

OTHER

- Rubber mounts

- Hydro mounts

- Adaptive mounts

- Electrical switchable engine mounts - Active Controls engine mounts

- Light weight material of 50% glass fiber & rubber modified Polyamide(PA)

- Fluid damping

- Rubber properties

- Inertia ring optimization

- Arc spring dampers

- Dual mass flywheel

- Pendulum absorbers

- MCU body mounts

- Selective catalyst reduction

- SCR - Green hydrogen

Material trends

At Premier Group, no matter what NVH challenge we encounter, we have the right mix and match of the lightweight material. To achieve this, we have various VAVE which are as follows

- Light weight solution by optimizing / benchmarking existing design

- Light weight solution by choice of right material (Steel, Aluminum, Rubber & Plastic)

- Light weight solutions based on smart modular designs to minimize tooling or child parts

Our success is achieved in different ways that include material substitution, gage thickness reduction, redesign of the part shape and size, elimination of redundant parts, and consolidation of several parts into one or two without sacrificing the overall structural integrity or functionality.

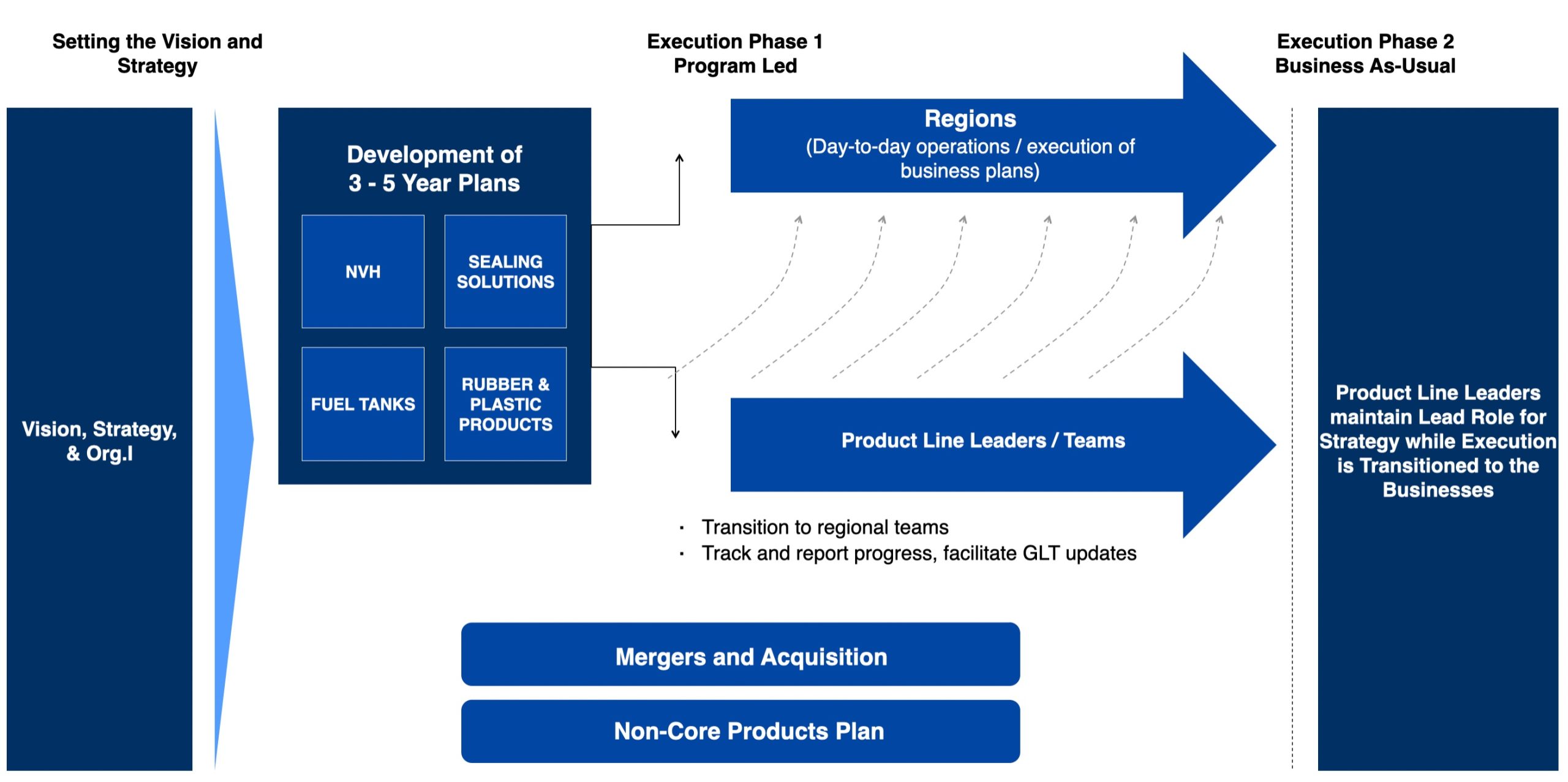

Product Line Strategy

Philosophy of ERIC institute

CONSTANT COMMUNICATION

WITH THE MARKET

We will develops innovative products that will lead the market by always listening to customer’s voices.

DEVELOPMENT FOR CUSTOMER SATISFACTION

We will satisfy the customer's needs by providing the high-quality product in the market.

SECURING GROWTHTECHNOLOGY

We will lead the change of technology trend through constant efforts and solidify the foundation of future growth by securing and cultivating excellent talented persons.

- Unique and innovative solutions

- ERIC partnered with customer to support them along with the entire product life cycle

- Supported customers on current and future mobility challenges

- Combined Advanced Engineering with System Simulation and Vehicle Testing for complete development of product from System Level Calculations to Product Level including Vehicle testing.

- Product Development via Black Box and Benchmarking of product (PS) to system level as Full Service Supplier (FSS)

- Testing of FEA, CAD, Materials, Development and Program resources under one roof.

- Reduced Lead time for Development

- Single Contact for Customer Engineering.

- On-going work on innovative projects like Batteries, BOTS, Polymers, Adhesives & Green Hydrogen

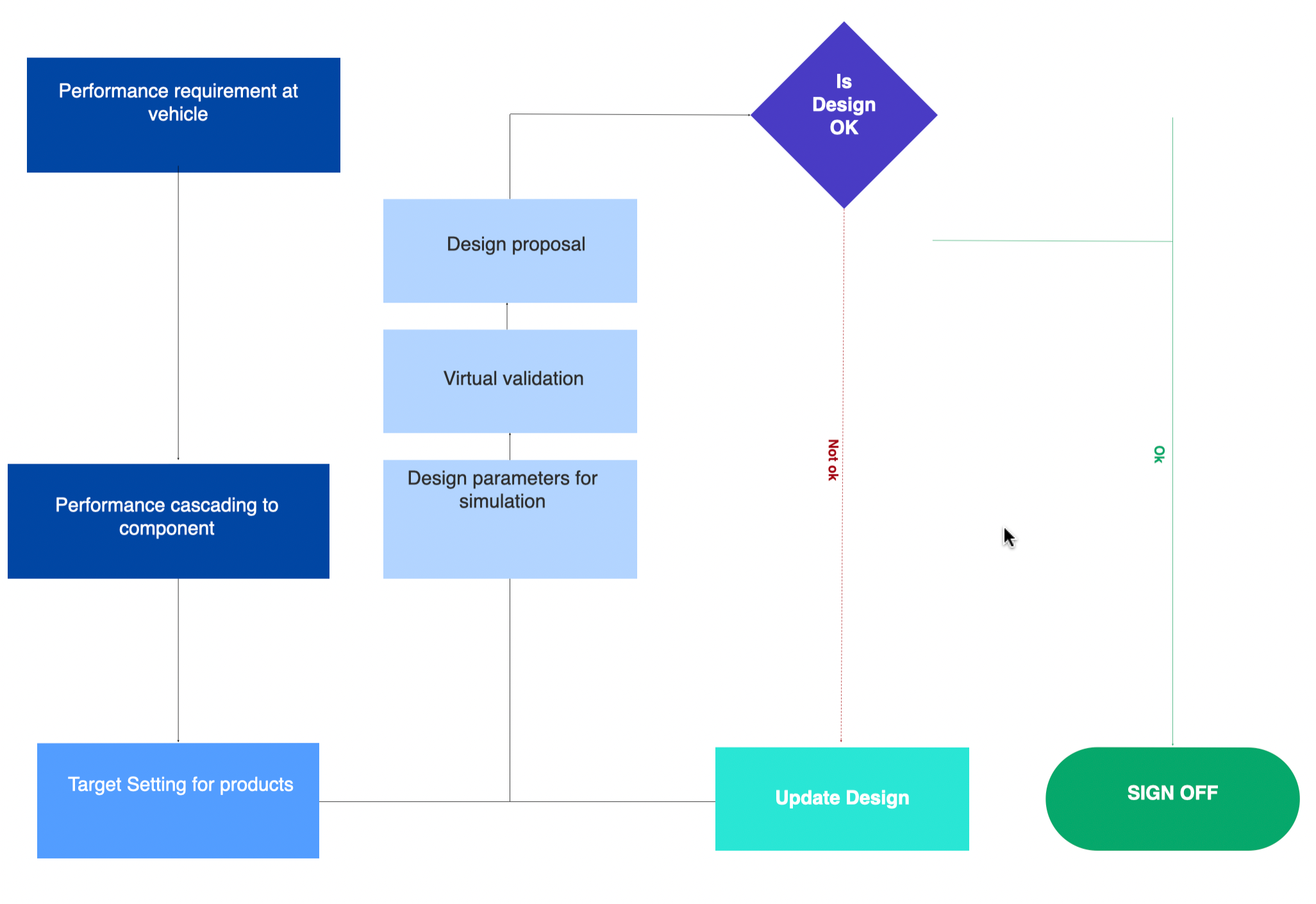

Design & Development capability

BENCHMARKING

- Vehicle performance evaluation

- Component performance evaluation

- Design details and parameters study

- Well established procedure for vehicle and component level NVH benchmarking

CONCEPT

- Vehicle packaging

- Product layout study

- Concept selection

SIMULATION

- 6 DOF simulation using ADAMS & Excel.

- Static, Dynamic Simulation to reduce product cycle time.

- Durability Simulation to predict the product life.

SYSTEM DESIGN

- Product design using software, based on simulation inputs

- Design considering vehicle level packaging constraints

VALIDATION

- Durability testing at test rig level

- Vehicle level evaluation of product prototypes

- Vehicle level mount durability at 4 poster rig and torture track

System design

DISCOVER OUR

PRODUCTS