The Anti-Roll Bar Bushing is made from flexible rubber or polyurethane materials and is placed between the anti-roll bar and the vehicle’s chassis. Its purpose is to secure the anti-roll bar in place while allowing it to flex and rotate as the suspension moves. By isolating the metal bar from the metal chassis, the bushing prevents direct metal-to-metal contact, reducing noise, vibrations, and wear on the suspension components. A properly functioning anti-roll bar bushing ensures that the anti-roll bar effectively distributes forces between the wheels, limiting body roll and enhancing the overall driving experience

At Premier Seals, our anti-roll bar bushings are engineered to provide exceptional durability, flexibility, and vibration isolation. We use advanced rubber and elastomeric materials that are resistant to wear, heat, and environmental conditions. Our bushings are designed to withstand the continuous movement and torsional forces exerted by the anti-roll bar, ensuring long-lasting performance and reliability. We collaborate closely with OEMs to design anti-roll bar bushings that meet the specific requirements of each vehicle’s suspension system. By ensuring precise fitment and optimal material properties, Premier Seals anti-roll bar bushings contribute to enhanced vehicle stability, improved handling, and a smoother, quieter ride.

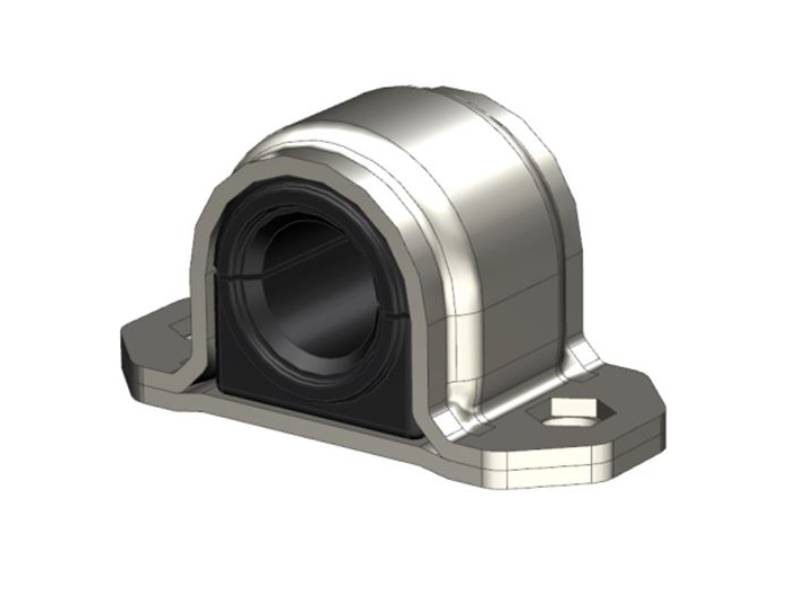

PRODUCT

Key Features