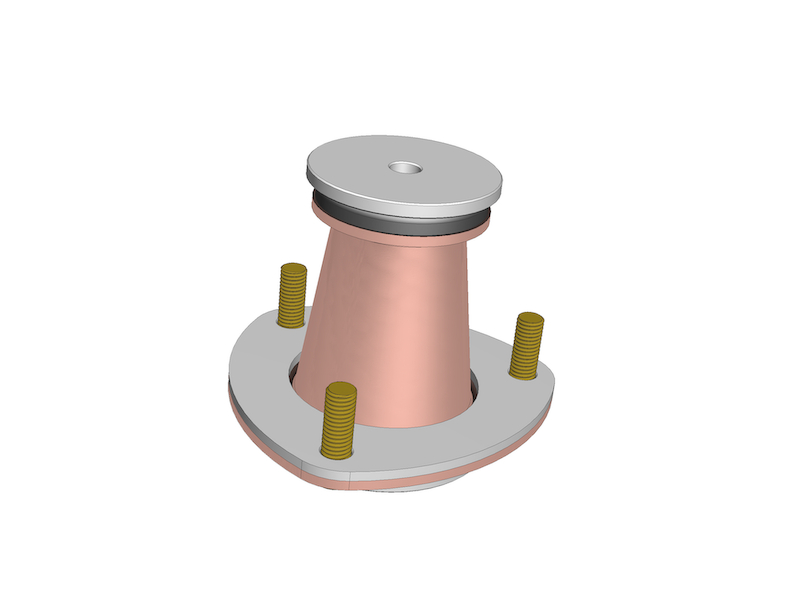

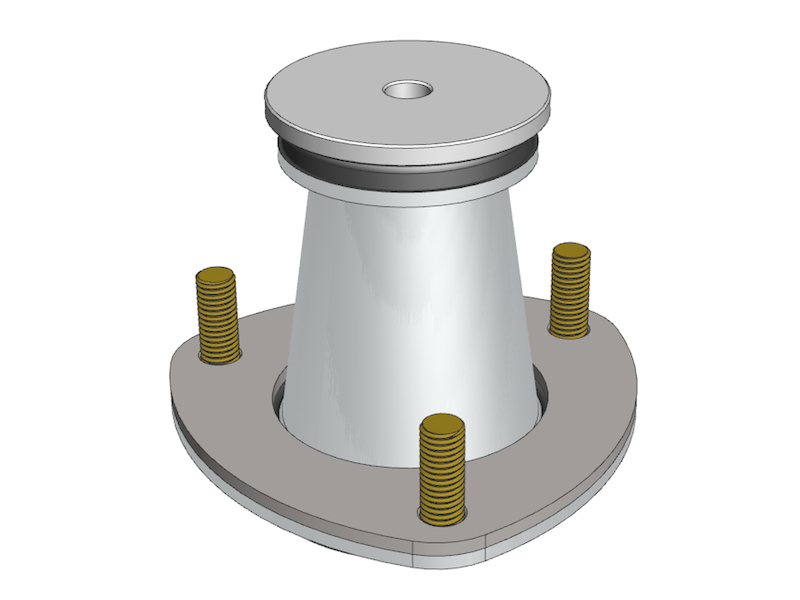

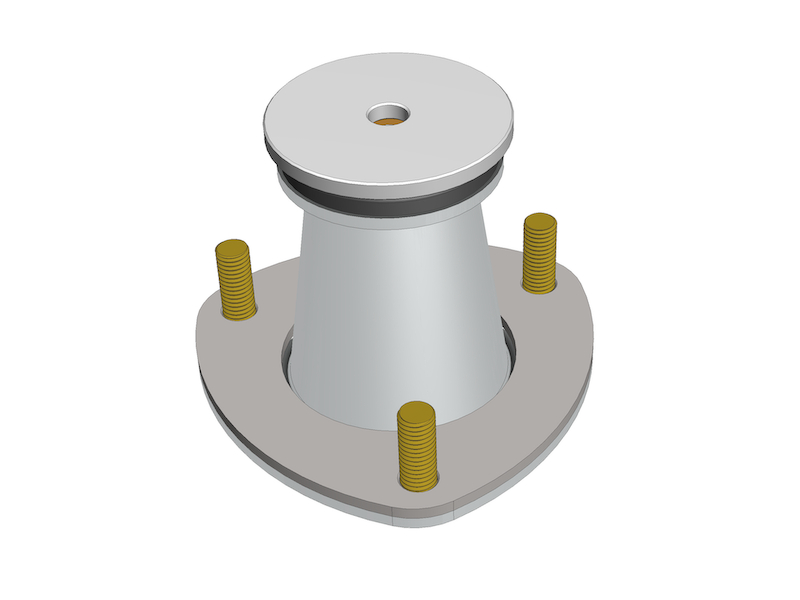

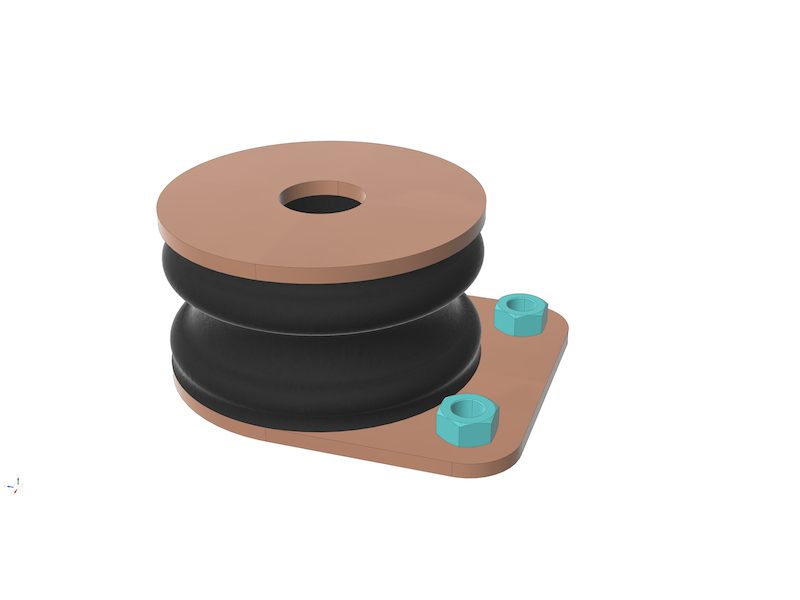

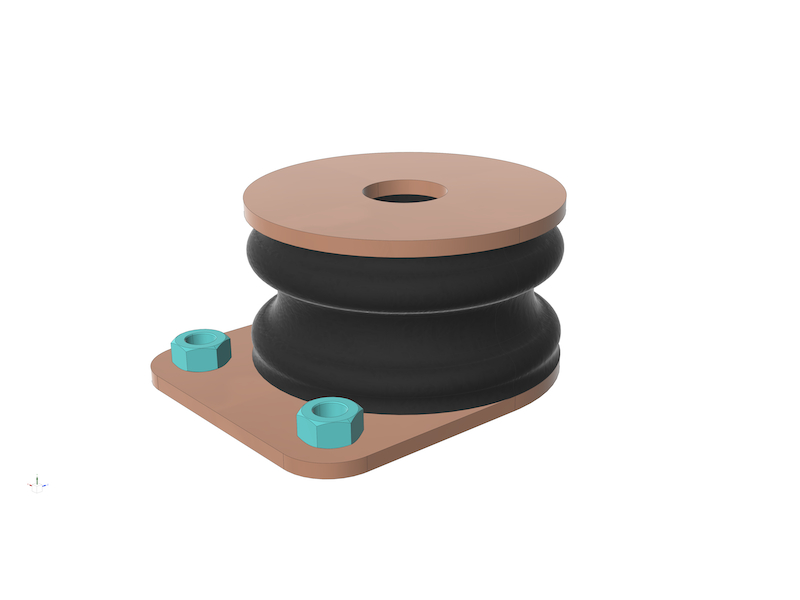

The Cabin Top Mount with Tilting Function is a specialized suspension component designed for heavy-duty trucks, commercial vehicles, and off-road machinery, where the driver’s cabin is mounted separately from the vehicle chassis.

PRODUCT

Key Features