In a rapidly changing world, three major trends—innovation, global connectivity, and the relentless march of globalization—are transforming industries, including rail transport. As the push for a greener planet gains momentum, the need for sustainable, safe, comfortable, reliable, and cost-effective rail systems is growing rapidly. At Premierseals, we aim to lead this transformation with innovative solutions designed to meet these evolving requirements.

Leveraging our renowned expertise in technology and materials from the automotive and other key industries, we bring a diverse and high-quality product range to the rail sector. Our advanced technologies are not only cutting-edge but also designed to enhance the efficiency and durability of rail systems. We provide tailored solutions that exceed expectations, supported by robust services and advanced in-house testing capabilities.

Our commitment to the highest industry standards ensures reduced maintenance, enhanced safety, and cost savings for our clients. With over decade of engineering and material innovation, Premierseals is the trusted partner to drive the future of rail mobility. Together, we can transform today’s challenges into tomorrow’s achievements, redefining rail transport for a greener, brighter future.

High-performance ball joint connecting the traction lever to the bogie, enabling precise and smooth power transmission with enhanced durability.

Essential for stabilizing roll motions in LHB FIAT Bogie, this robust ball joint ensures optimal lateral balance and ride comfort.

Designed to absorb dynamic forces and vibrations, providing flexibility and stability in the central traction system of the bogie.

A resilient rubber component that limits lateral movements, ensuring controlled dynamics and protecting the bogie structure.

A durable and precision-engineered component that facilitates smooth pivoting action, minimizes vibrations, and enhances the operational efficiency

Absorbs vertical shocks in the primary suspension system, enhancing passenger comfort and reducing structural stress.

Provides cushioning and vibration isolation in the primary suspension, ensuring a smoother and quieter ride.

Specially designed to limit longitudinal motion, protecting the bogie and enhancing ride stability.

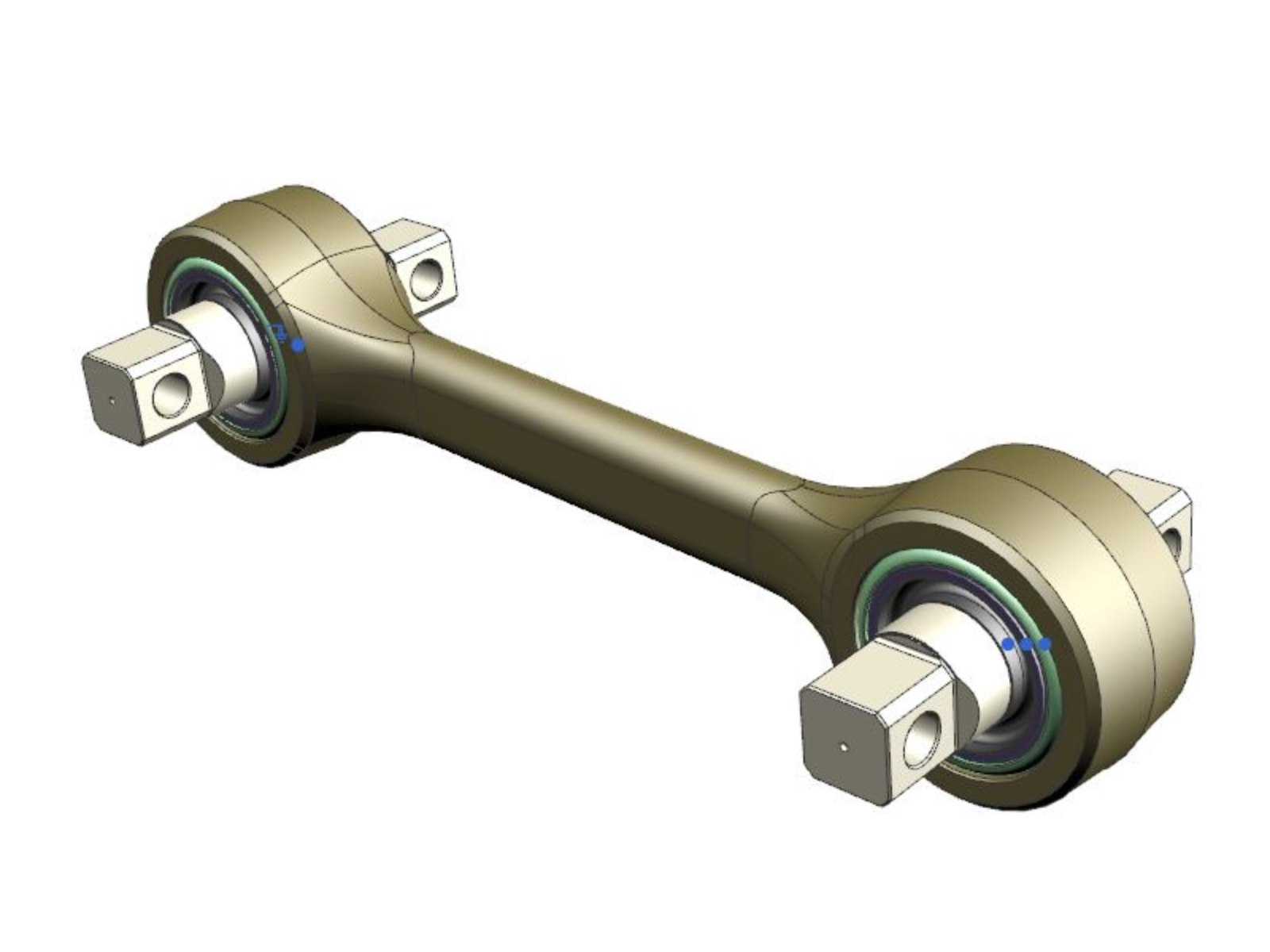

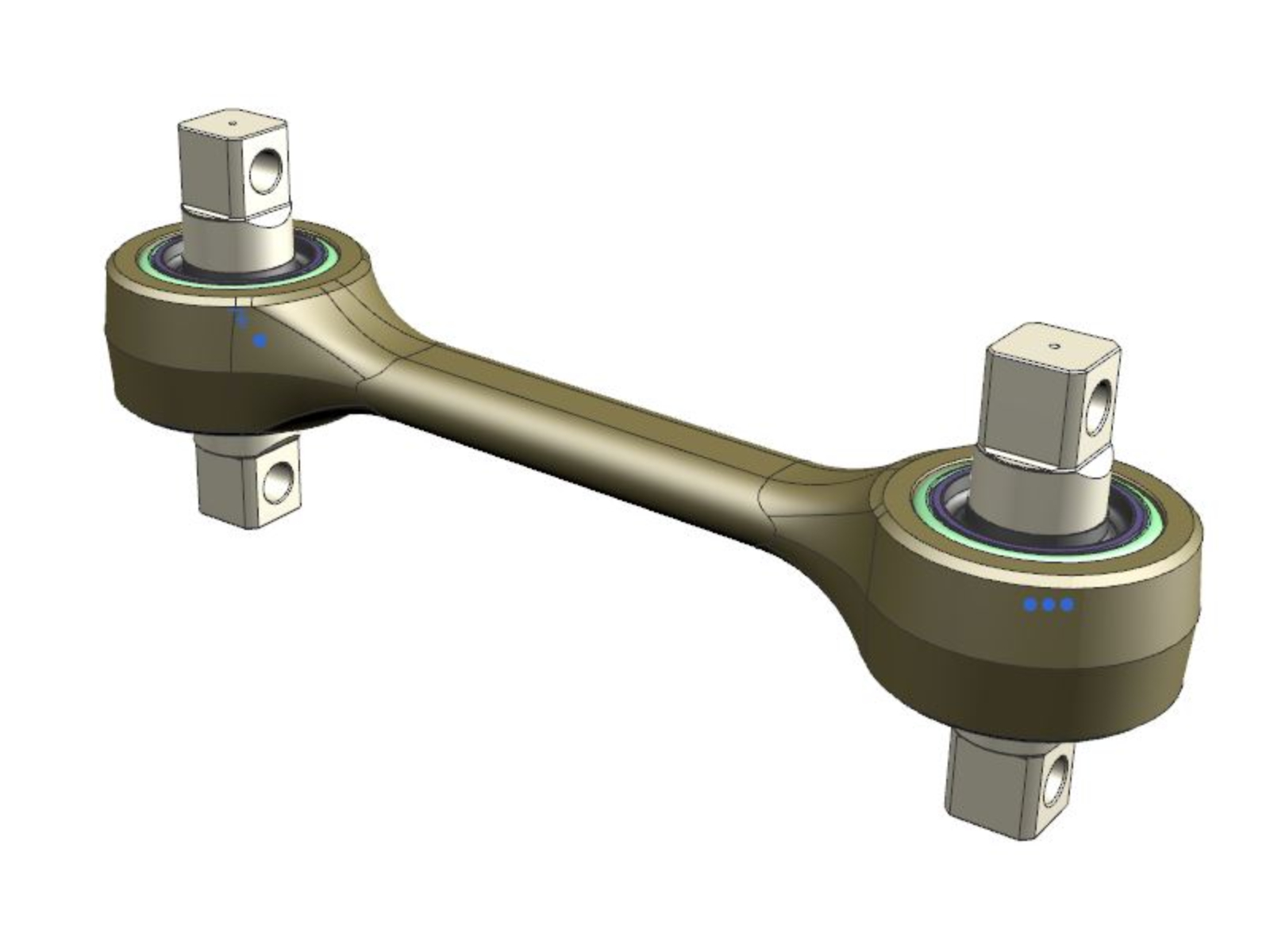

The stabilizer link, also known as a sway bar or anti-roll bar, connects both sides of the suspension system in a bogie to reduce body roll and improve stability during cornering or uneven terrain. It distributes weight evenly across the bogie, maintaining balance and traction, while also allowing controlled independent suspension movement to handle uneven surfaces effectively.

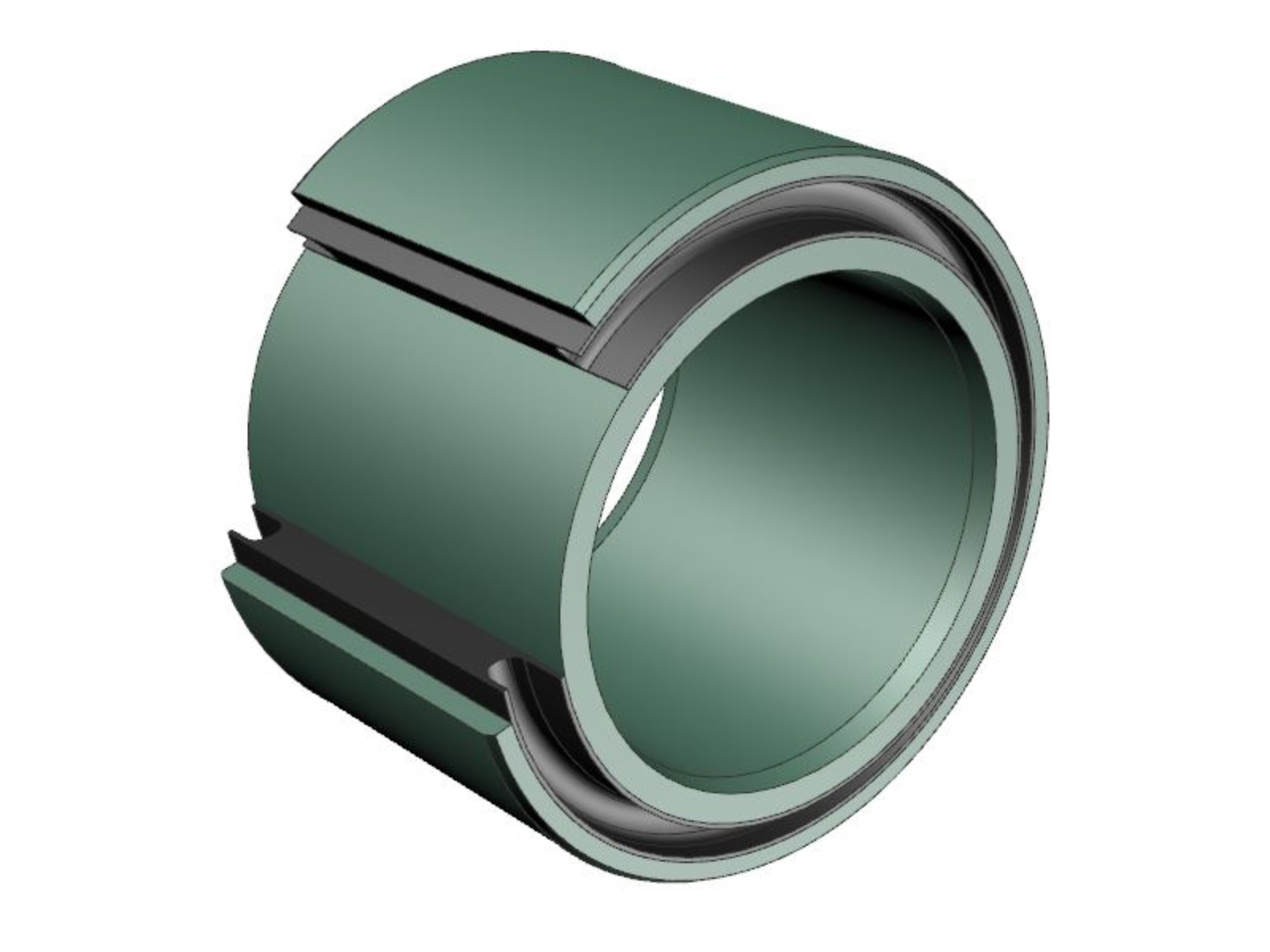

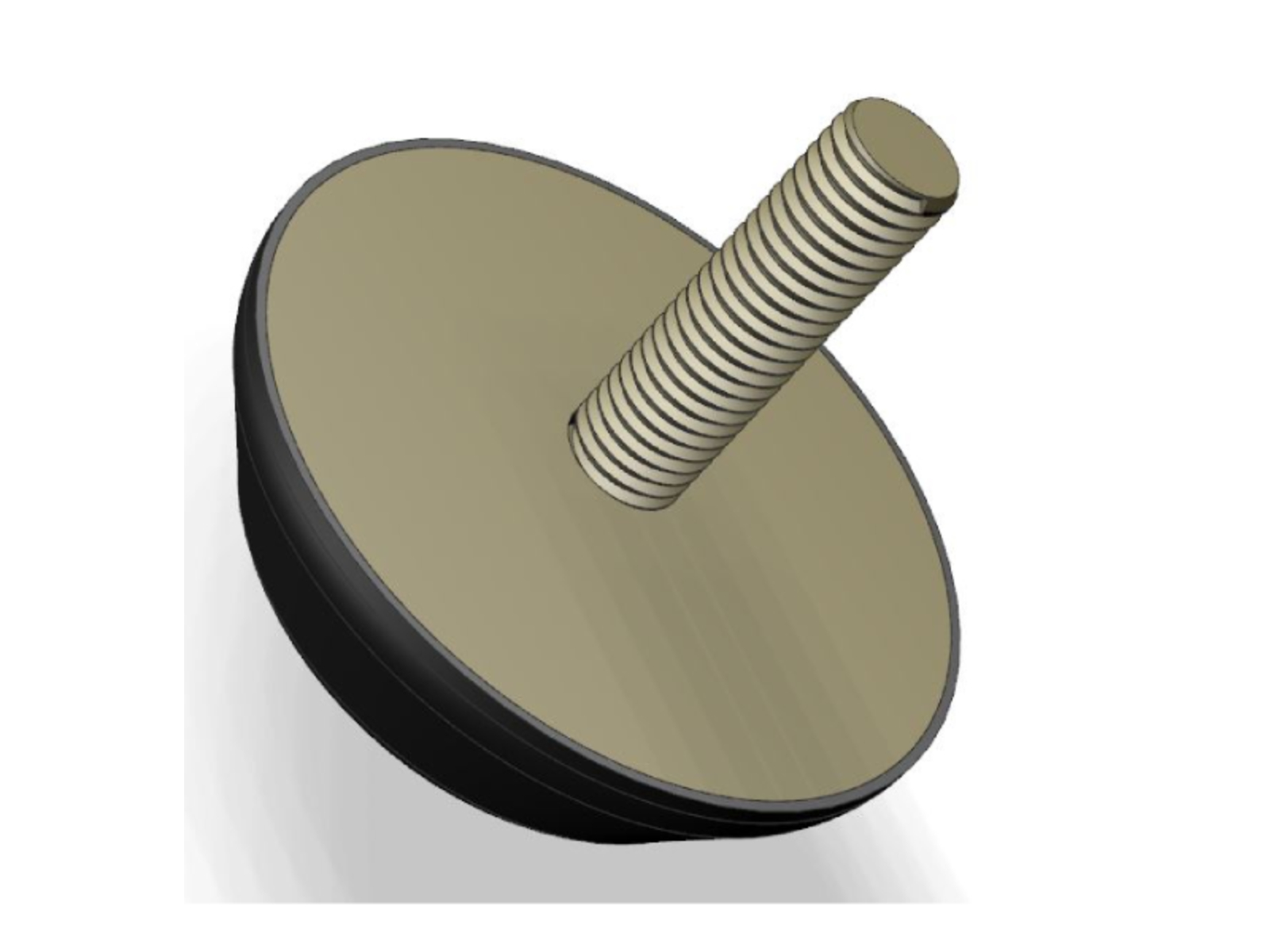

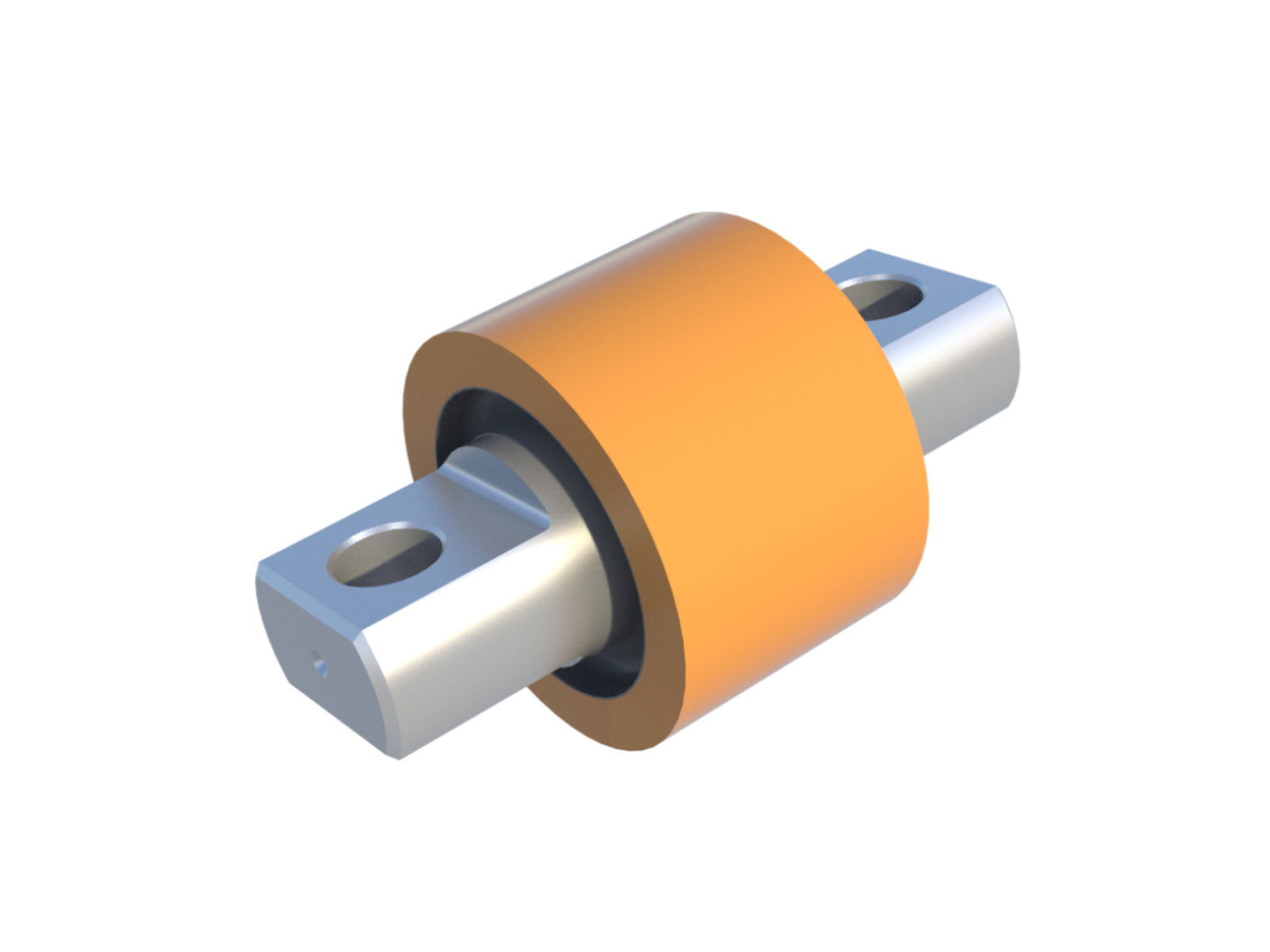

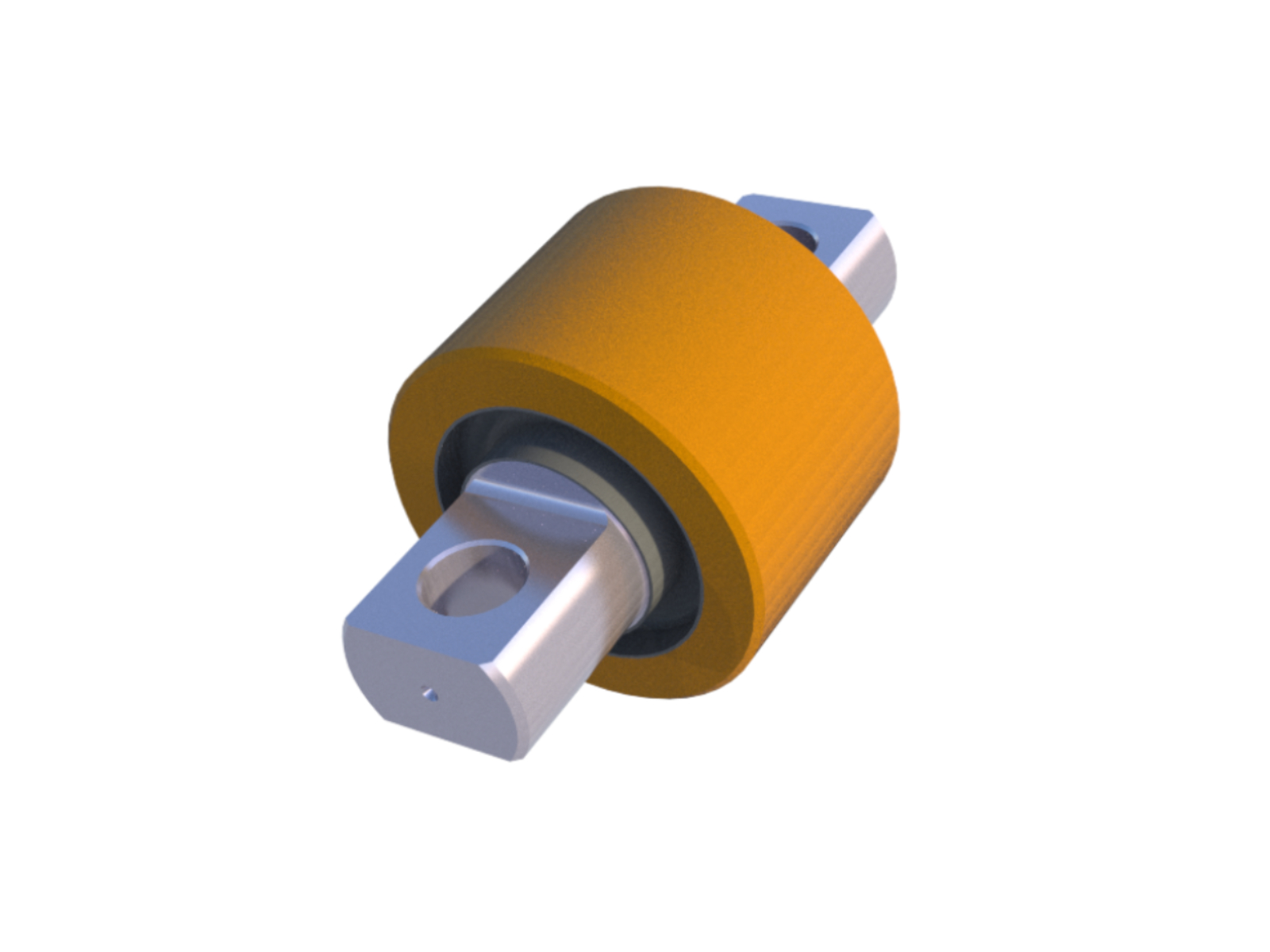

The controlled arm rubber metal bush, also known as the control or trailing arm bush, connects the wheel assembly to the bogie frame and absorbs vibrations, shocks, and impacts for a smoother and more comfortable ride. Designed with a rubber element bonded to metal sleeves, it provides elasticity, structural support, and vibration isolation, enhancing the stability, handling, and durability of the bogie's suspension system.

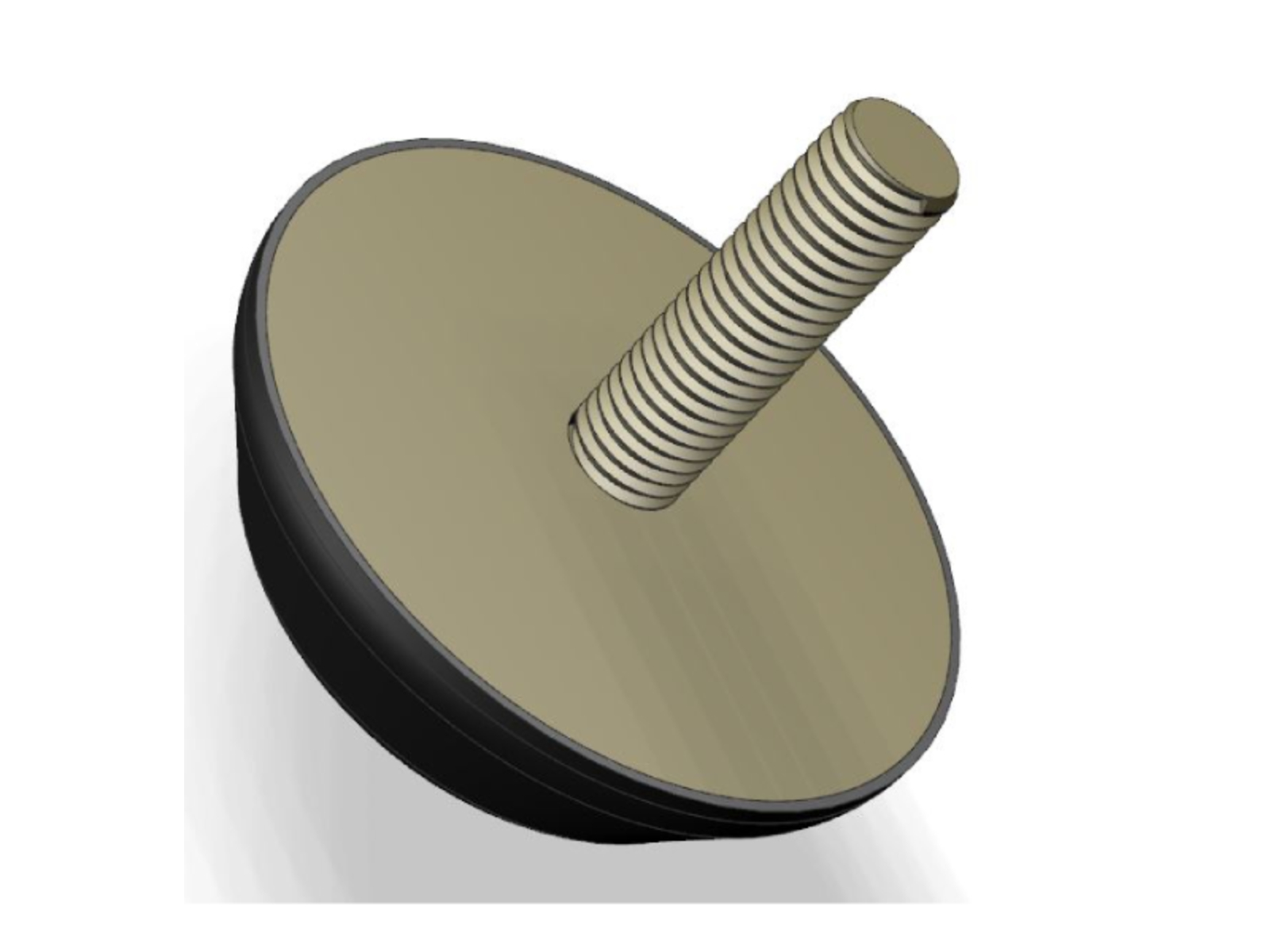

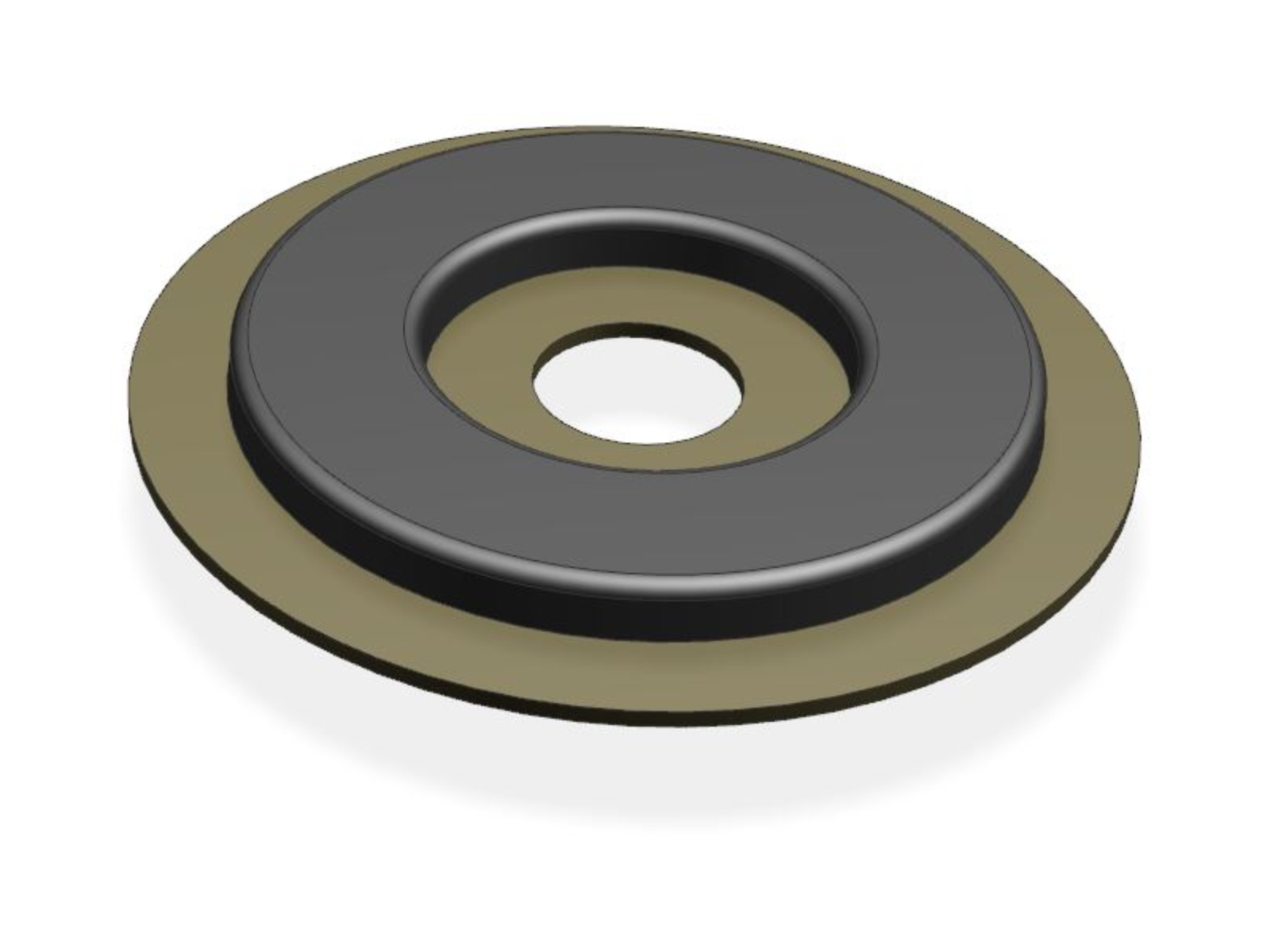

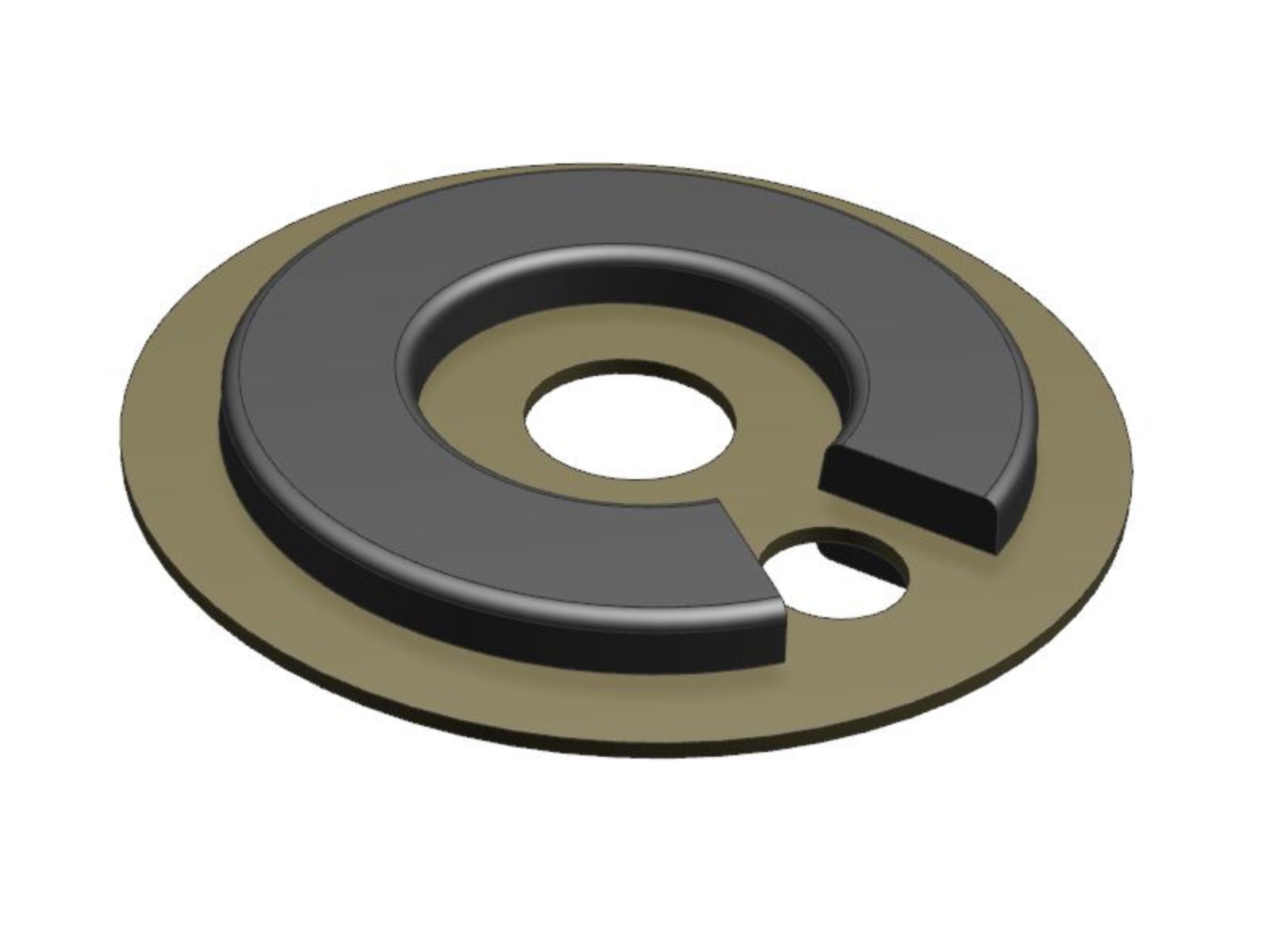

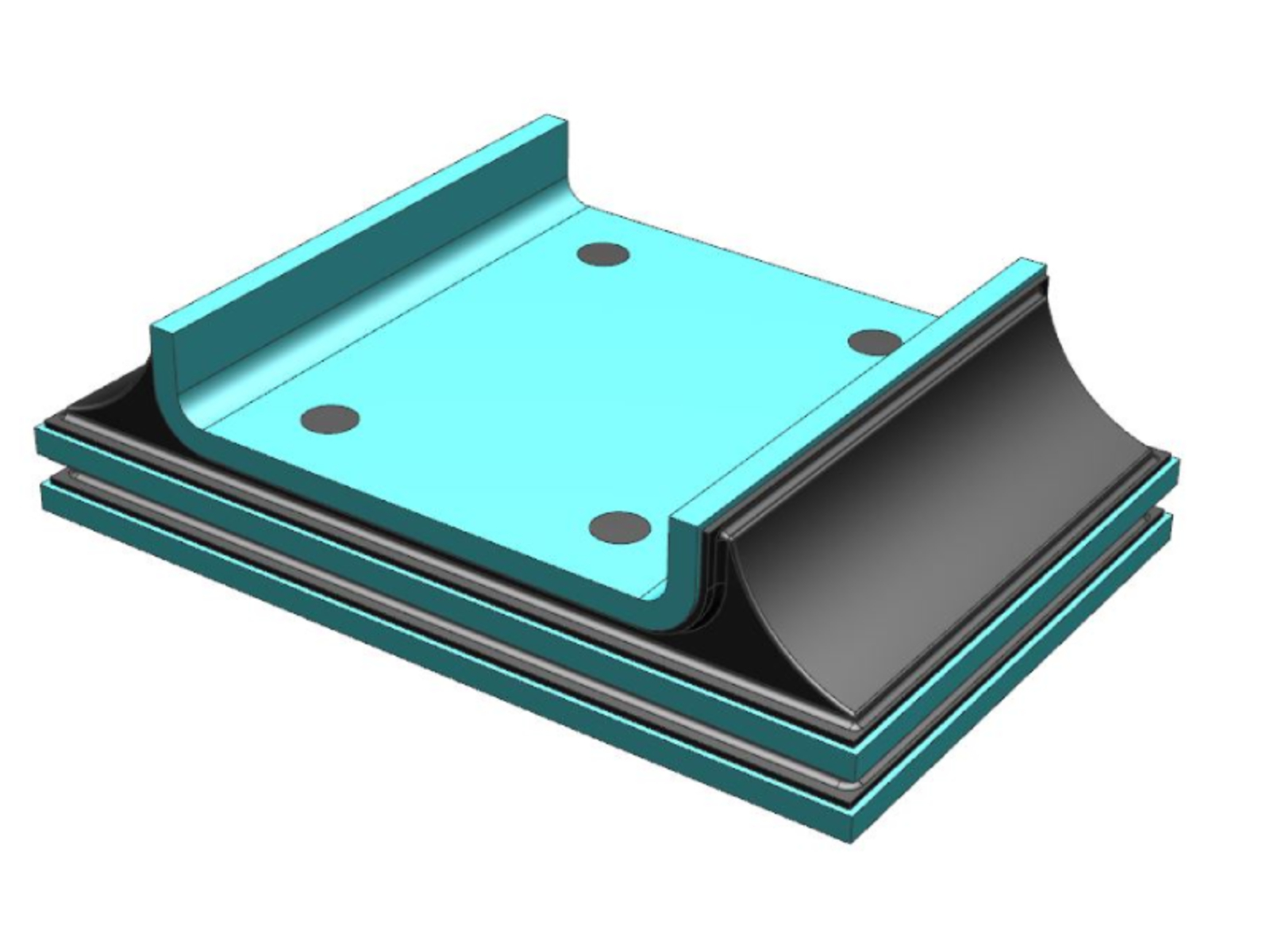

The rubber pad in a bogie's primary suspension serves to absorb shocks, distribute loads, isolate noise and vibrations, and enhance lateral stability. It cushions vibrations from uneven tracks, evenly distributes the vehicle load, minimizes noise, and limits excessive lateral movement, ensuring passenger comfort and vehicle safety

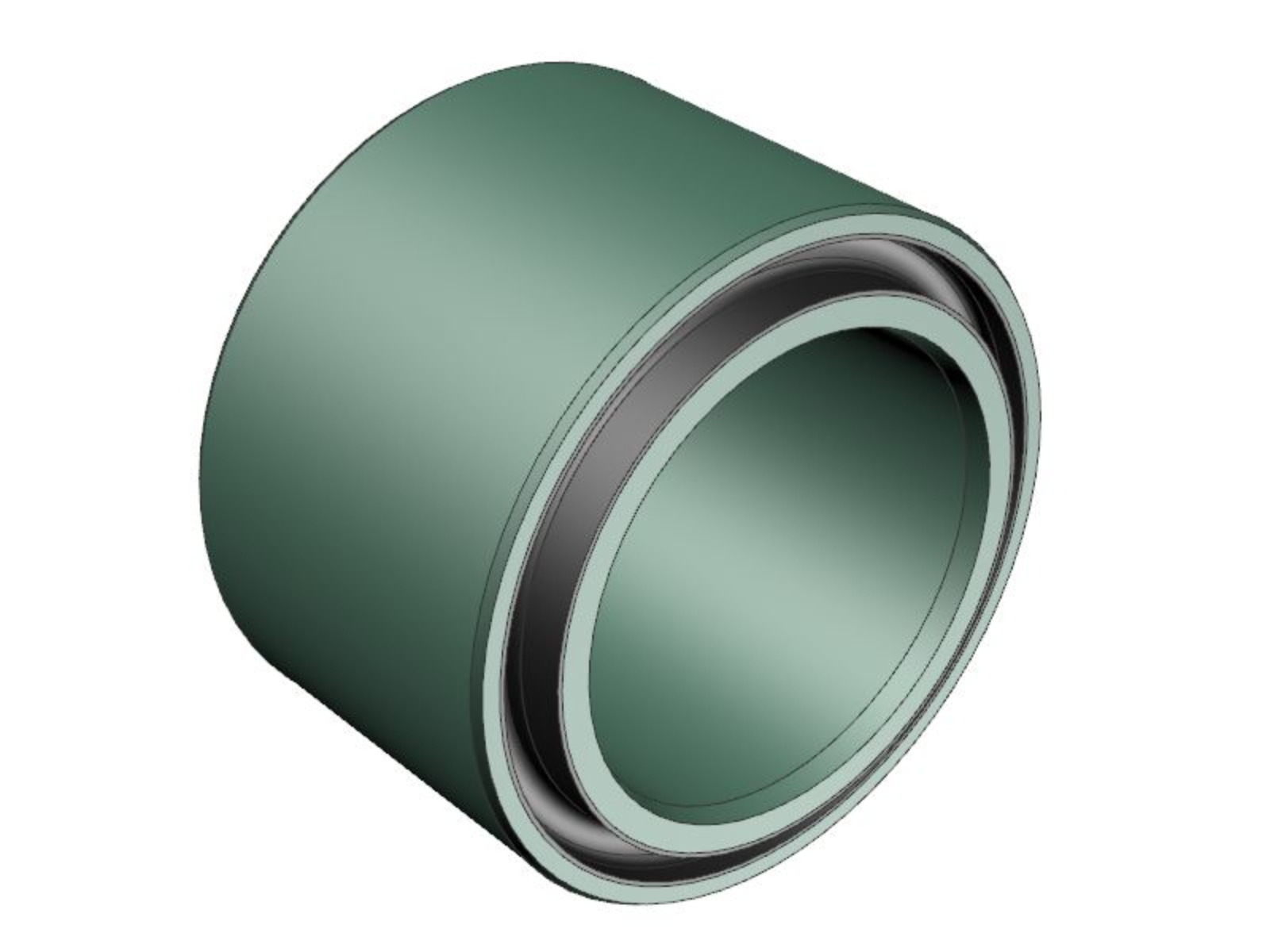

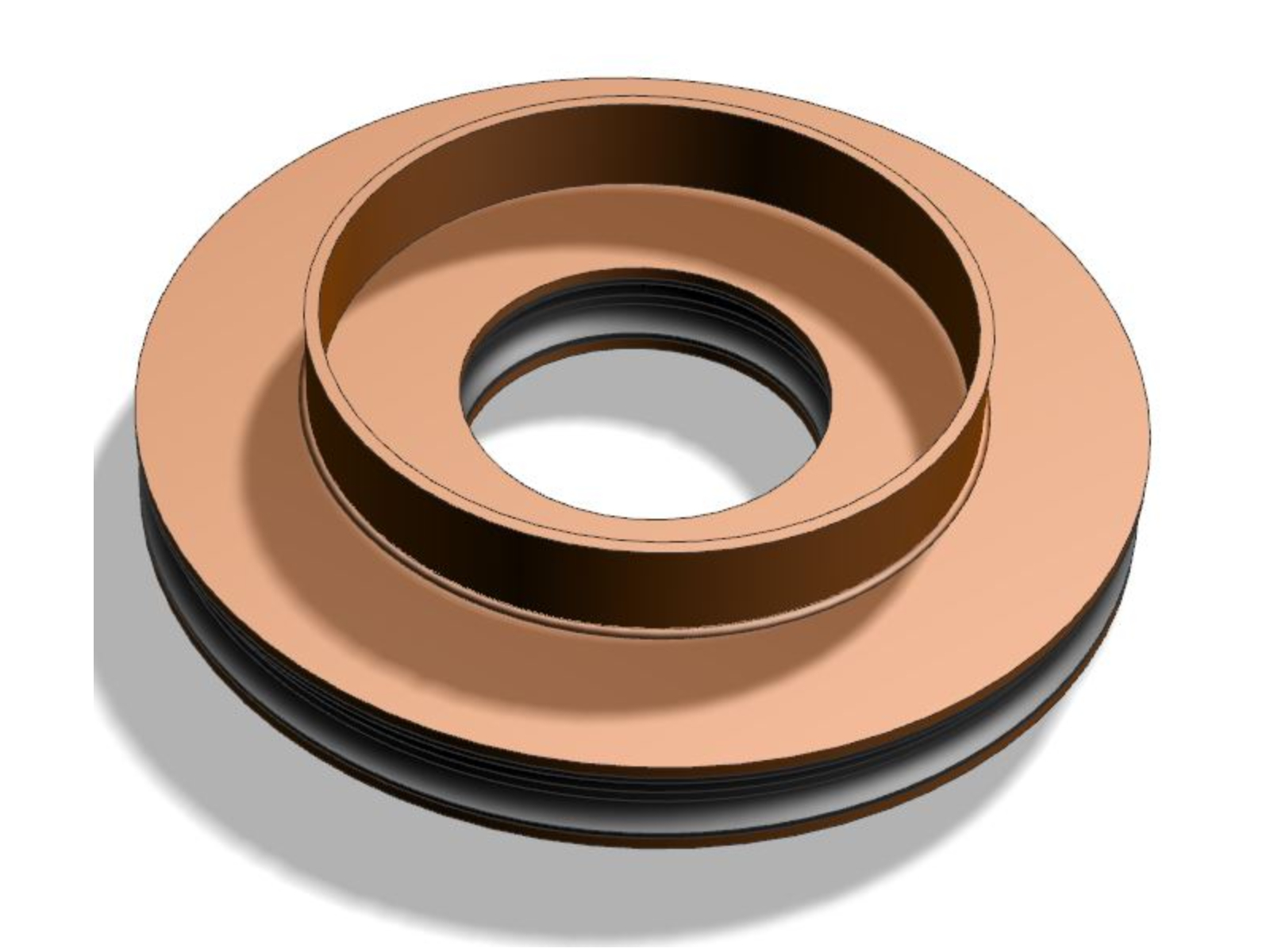

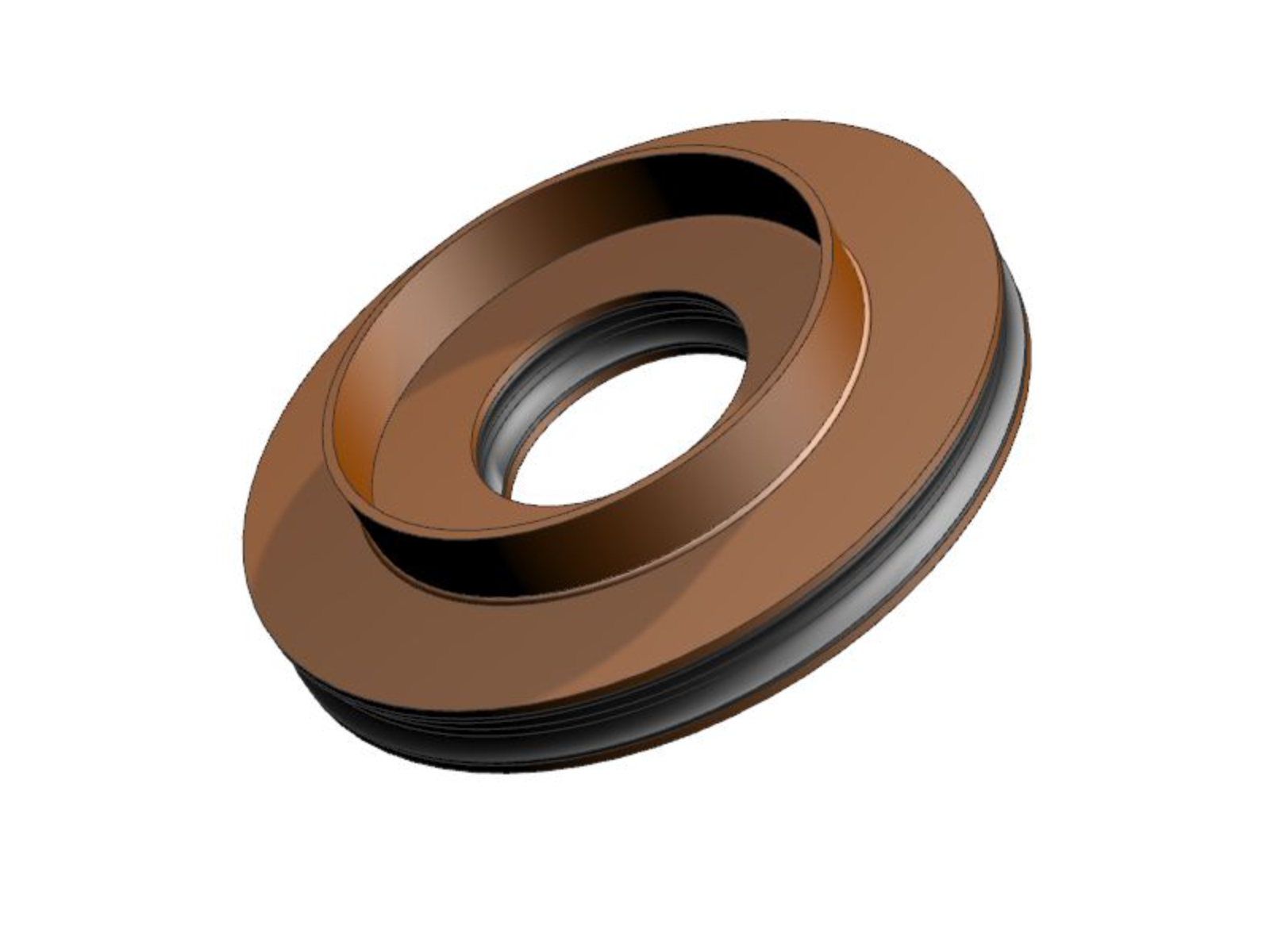

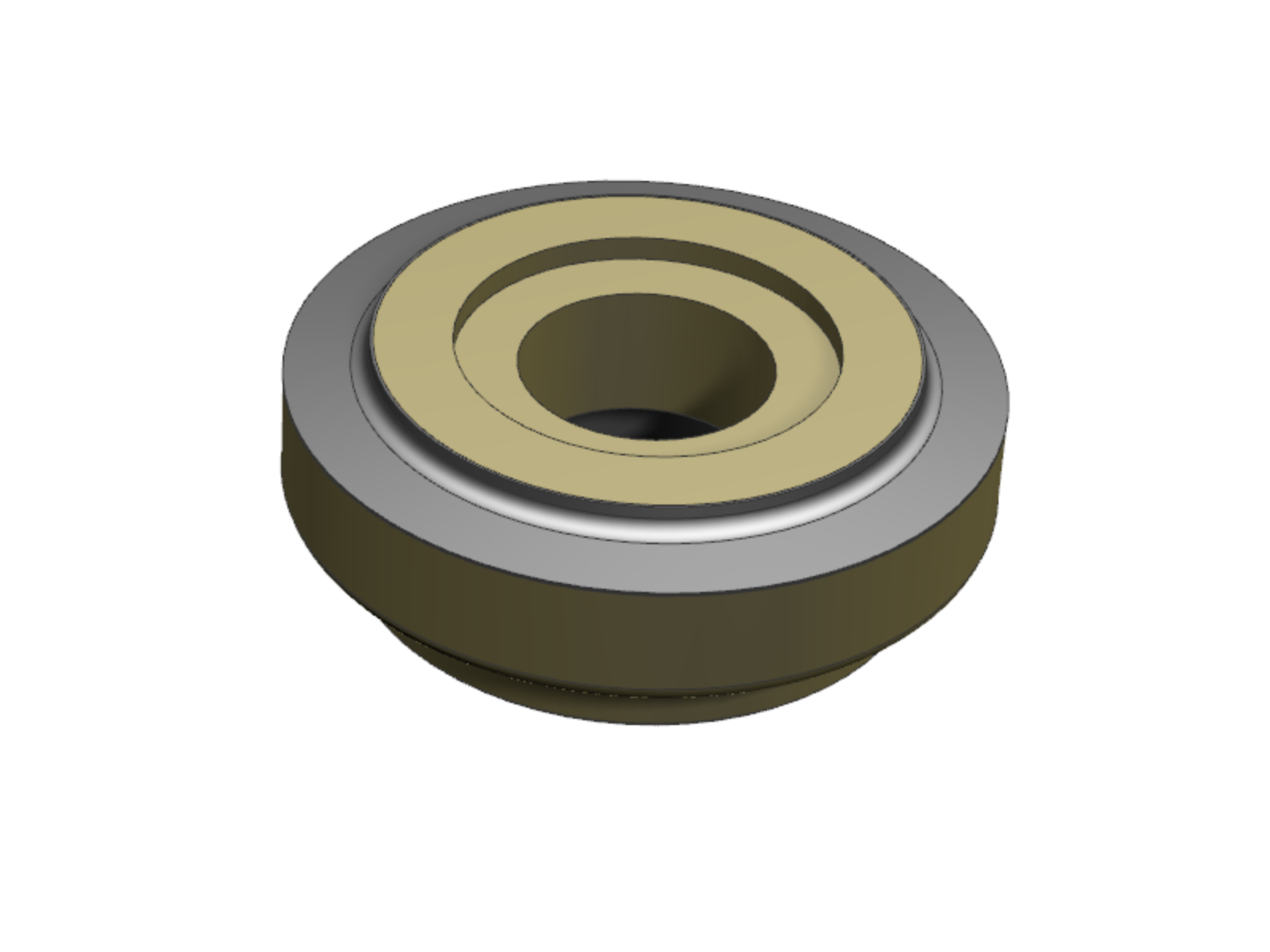

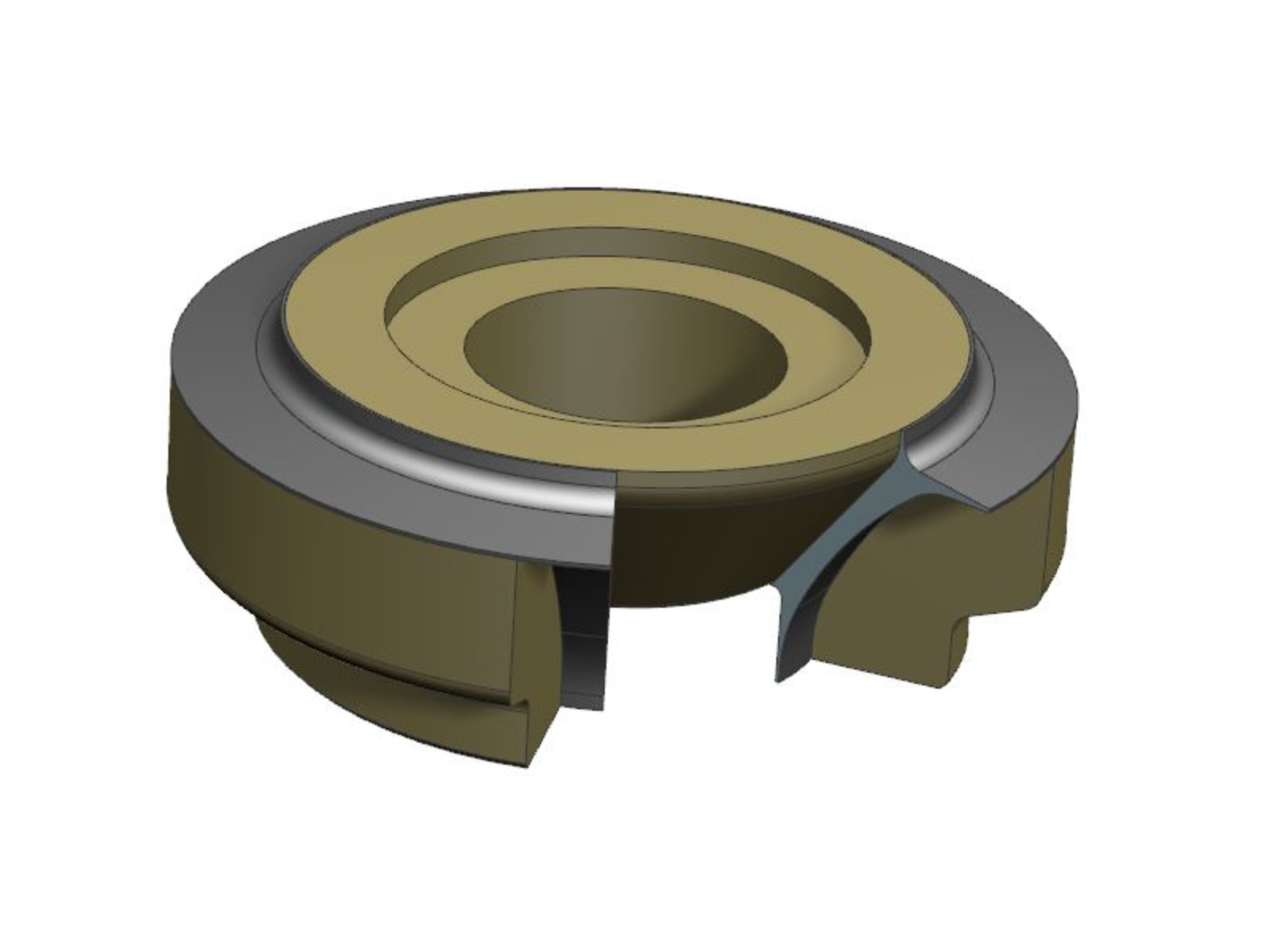

The Center Pivot Bush, also known as the Center Pivot Bearing, enables the bogie to pivot and adapt to track curves and irregularities, ensuring stable rail contact. It reduces lateral forces by absorbing and distributing them during curves or uneven conditions, improving stability and minimizing stress on the bogie. Additionally, it dampens vibrations and impacts, enhancing passenger comfort and protecting bogie components.

The side bumper in a bogie, or lateral buffer, absorbs lateral forces during train operations, stabilizing the bogie and reducing swaying on curves or uneven tracks. It enhances passenger comfort by dampening lateral movements for a smoother ride. Additionally, it protects bogie components from impacts and reduces noise and vibration, ensuring structural integrity and a quieter environment.

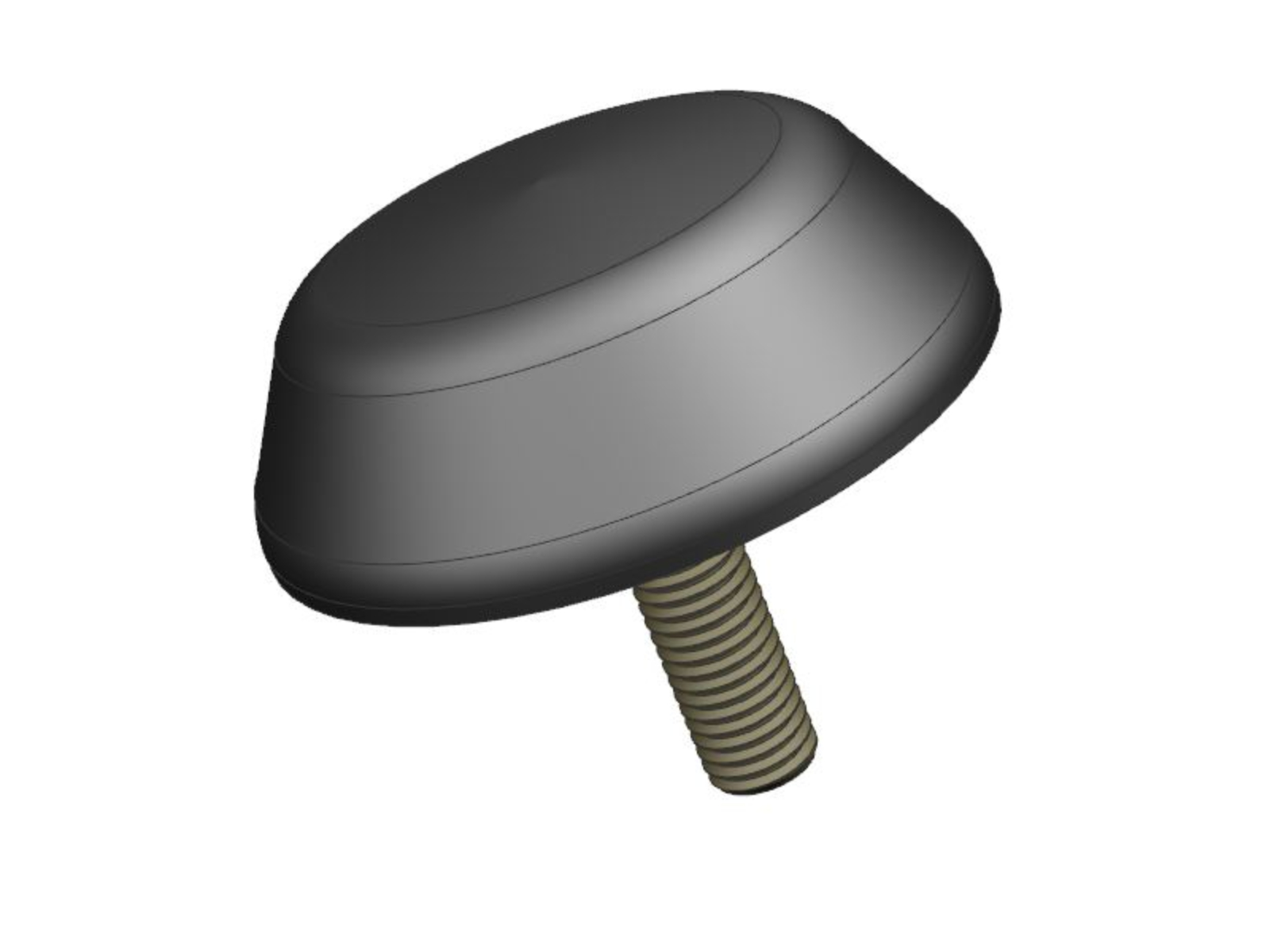

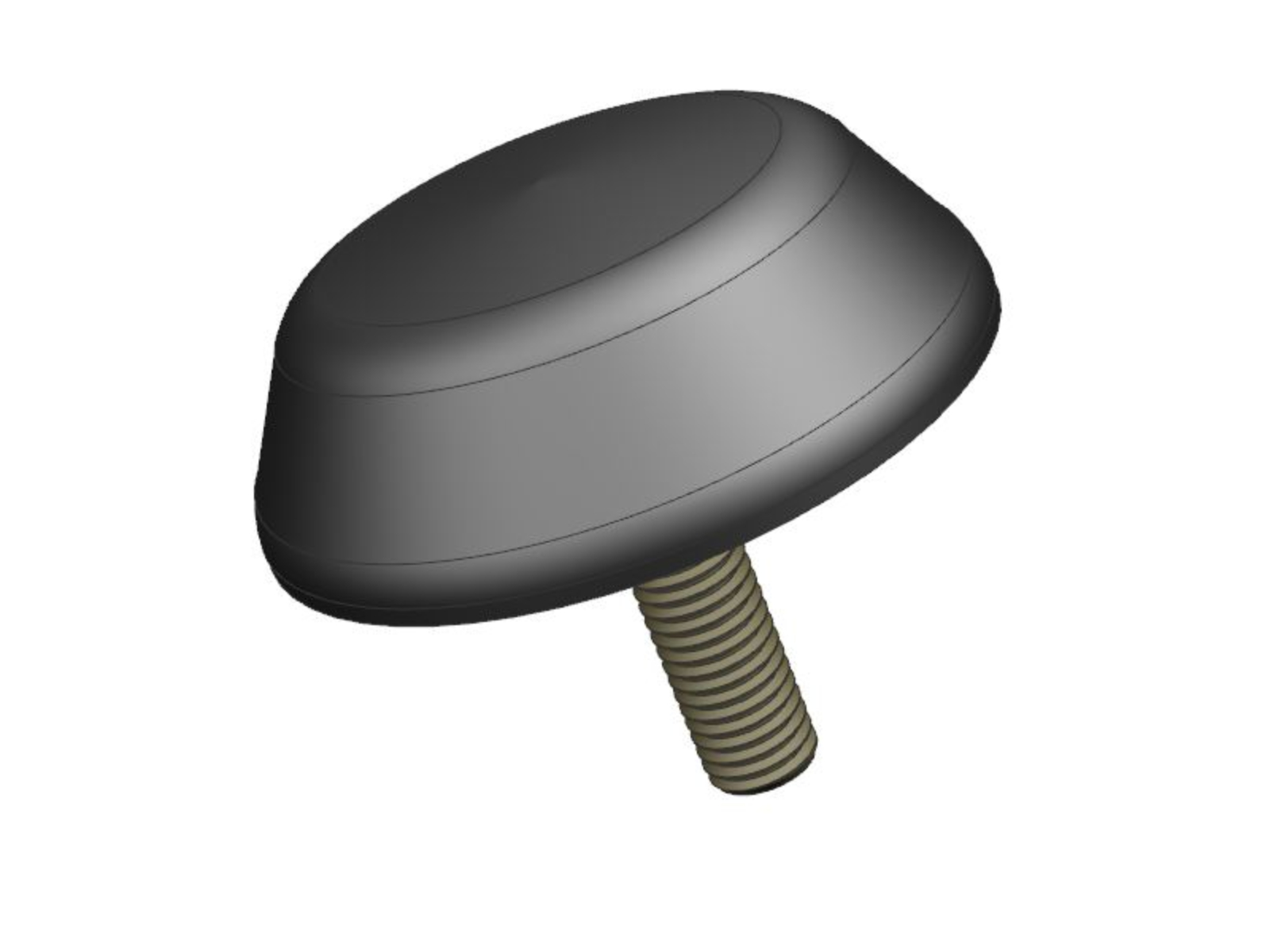

The primary bump stop in a bogie absorbs vertical forces from track irregularities, cushioning impacts and ensuring a smoother ride for passengers. It protects the bogie structure by preventing excessive compression of suspension components and limiting vertical travel. Additionally, it controls suspension movement, maintaining stability and preventing bottoming out during operations

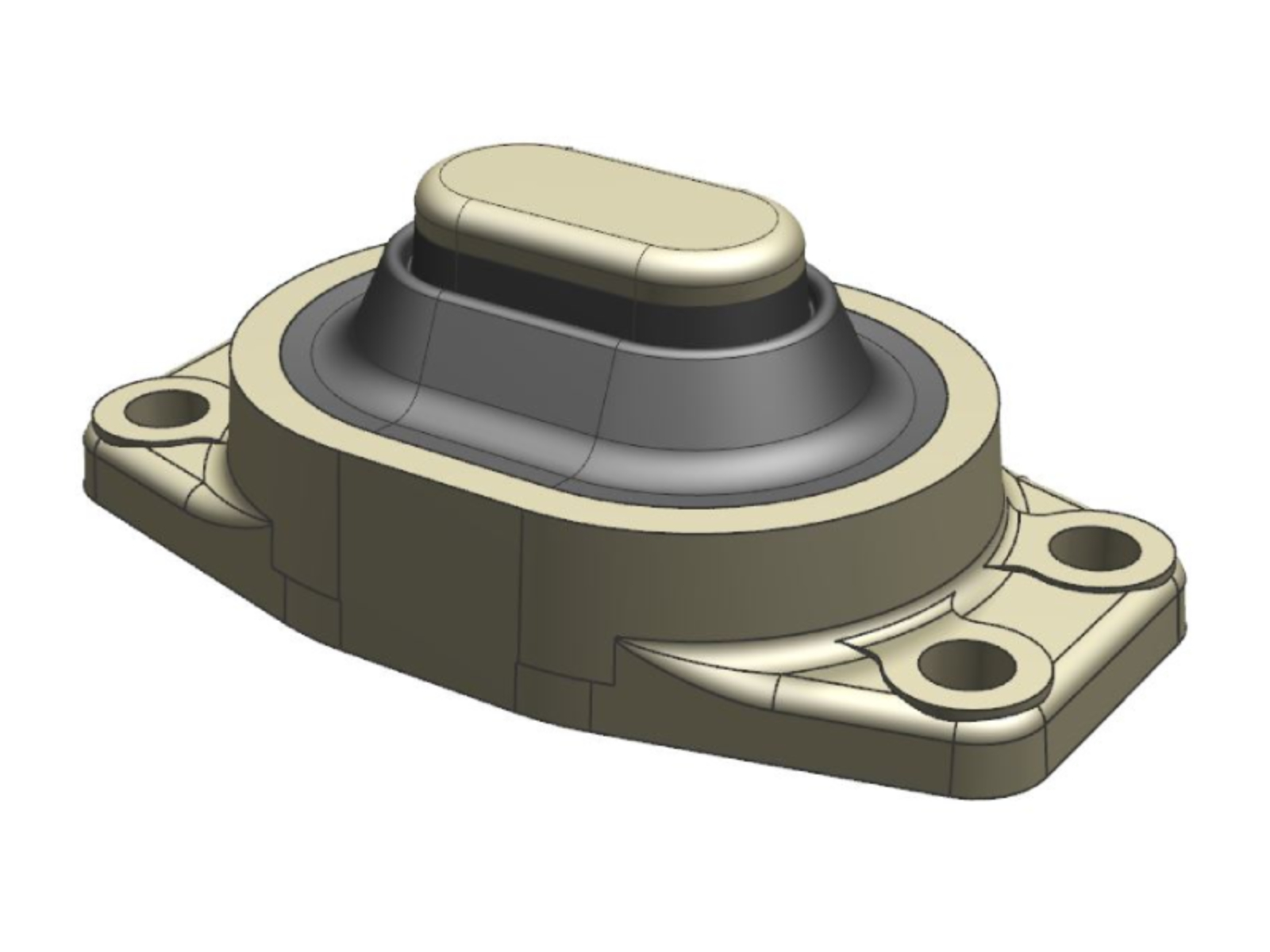

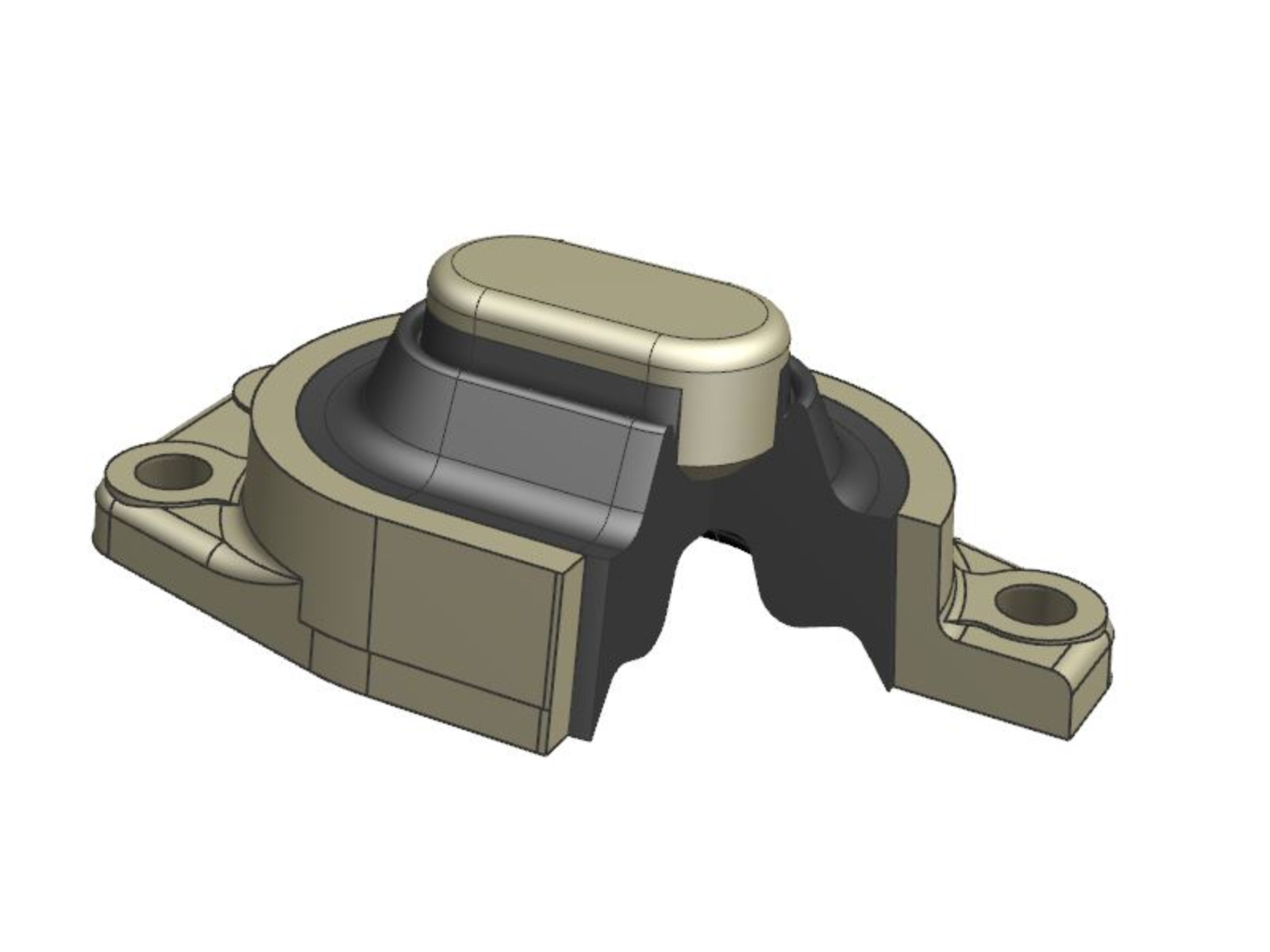

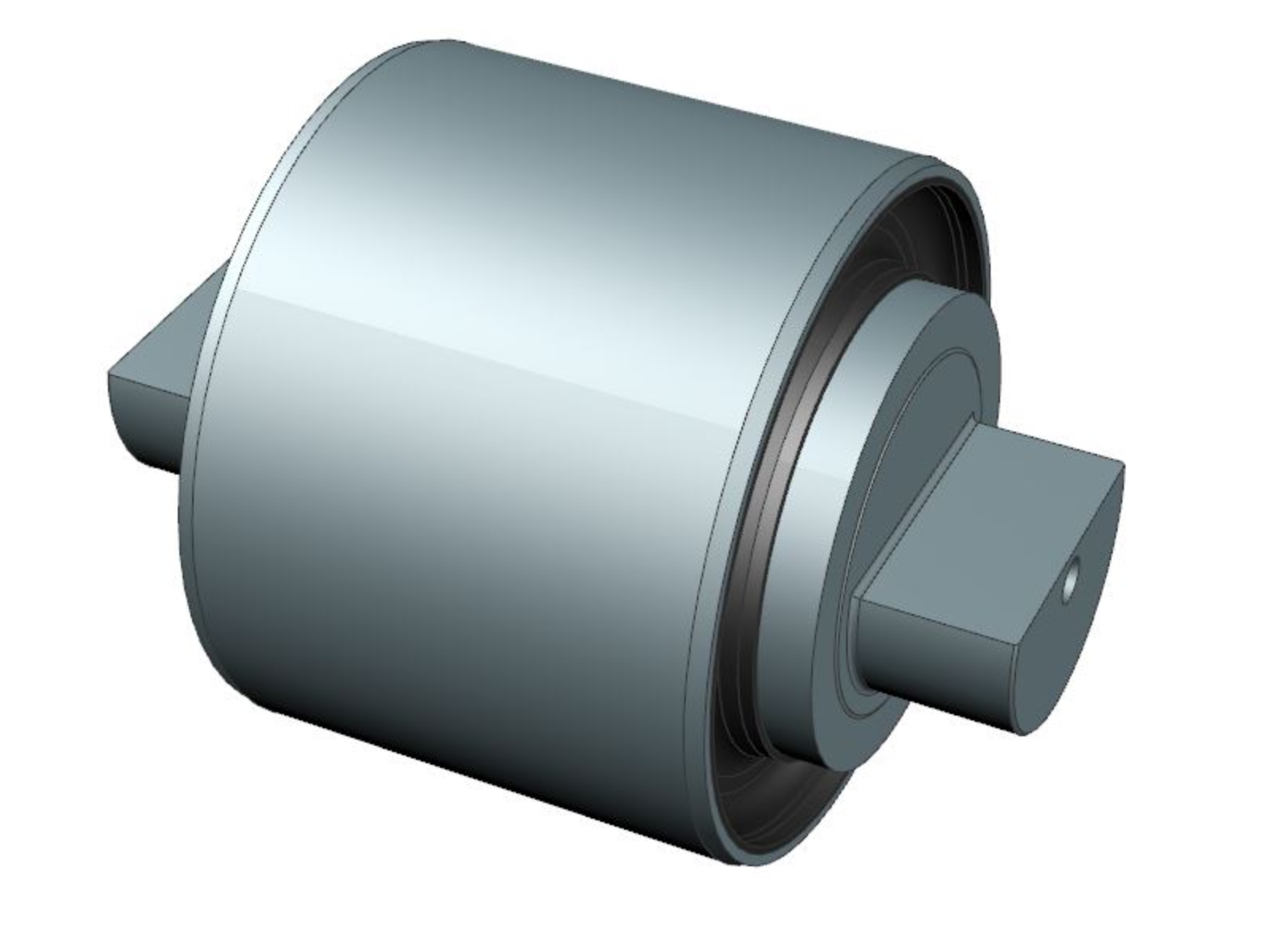

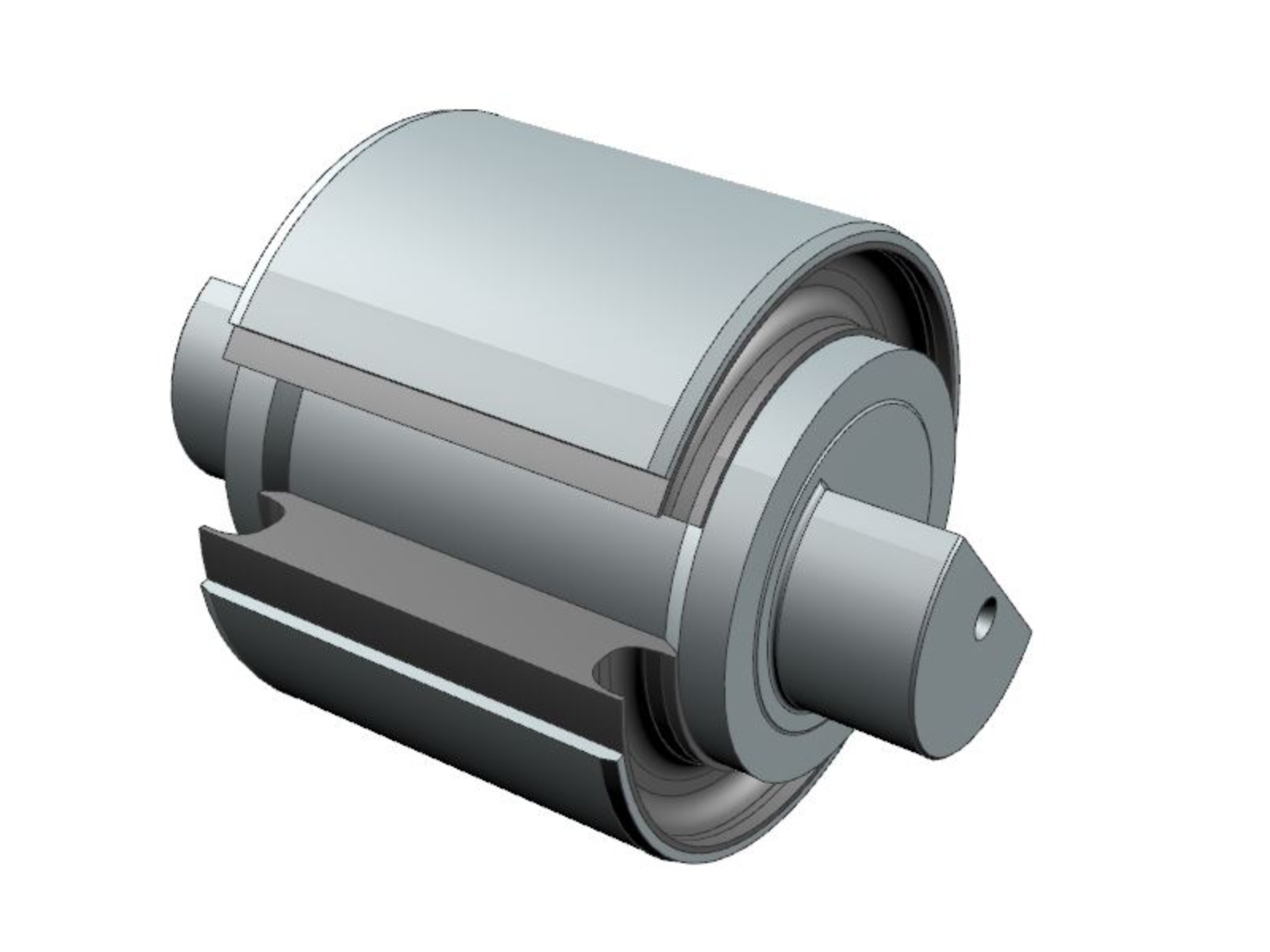

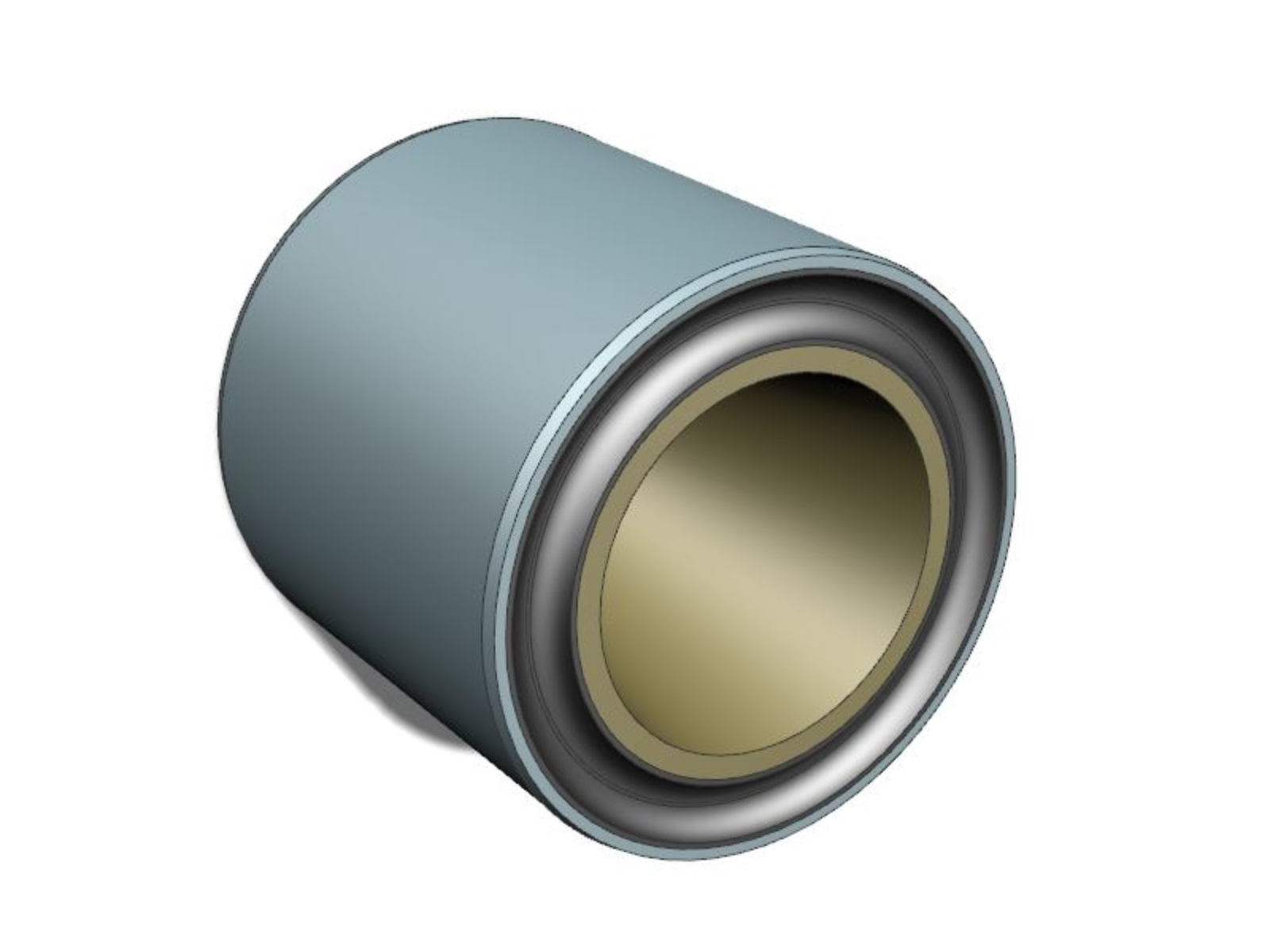

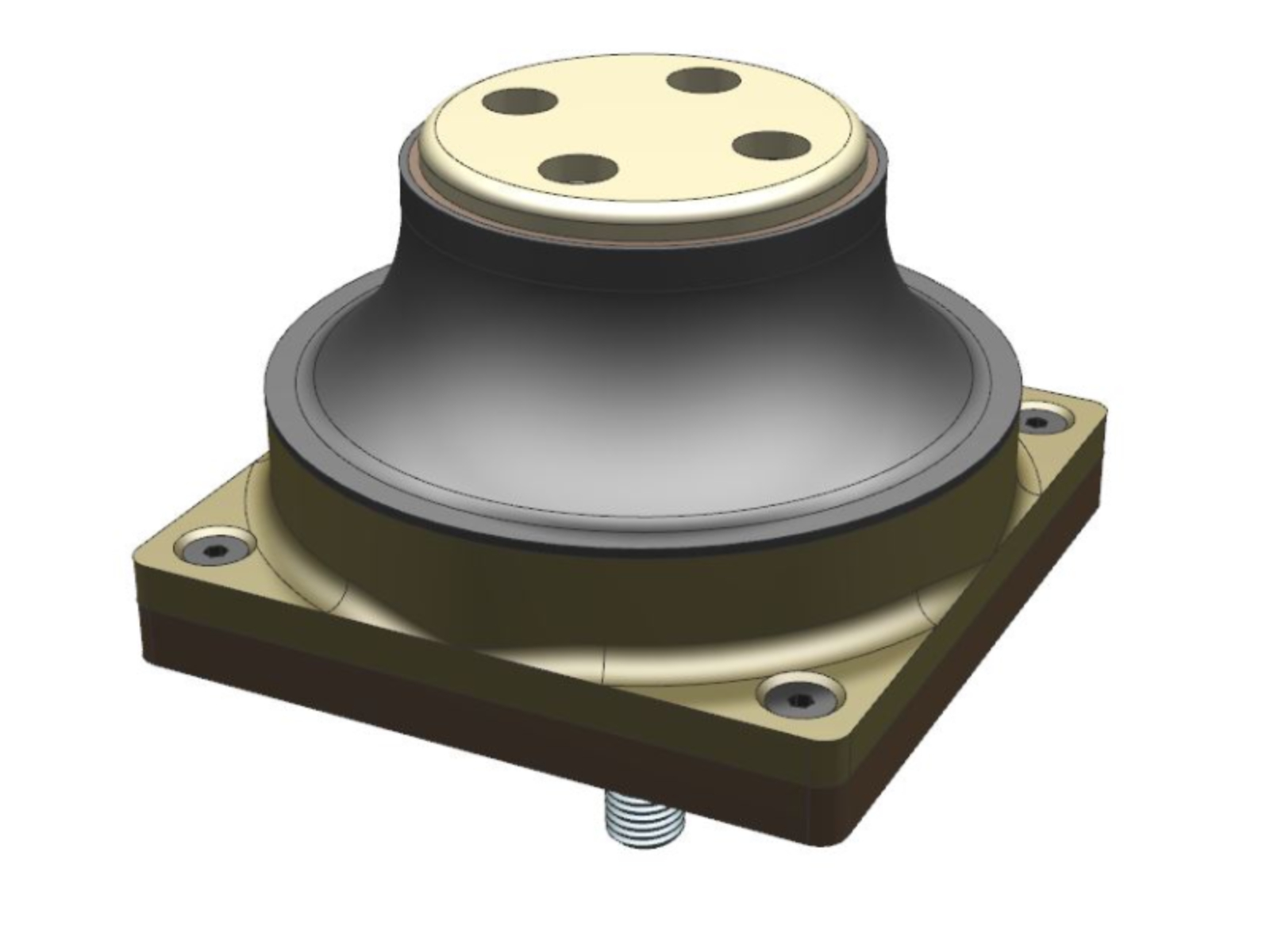

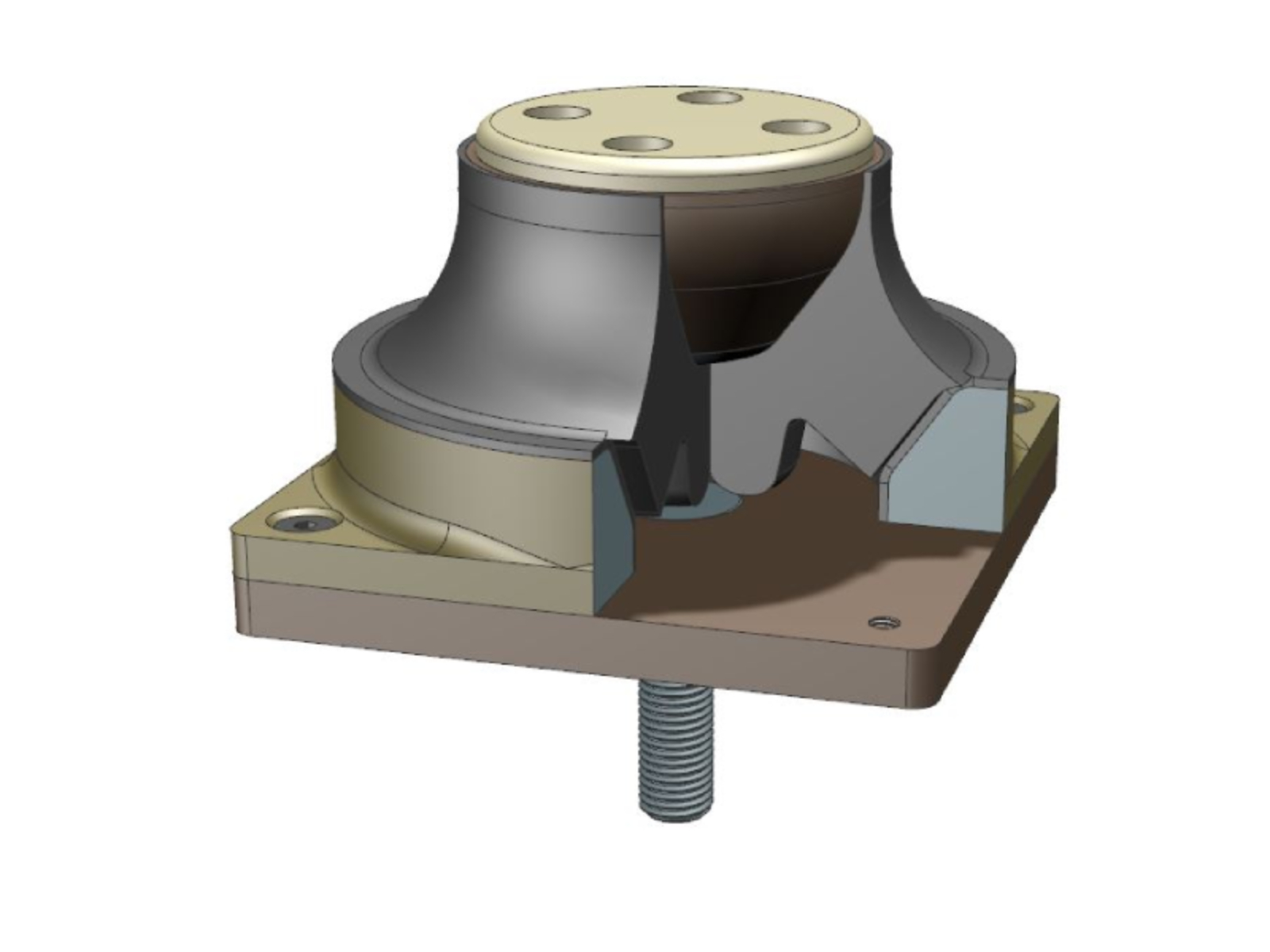

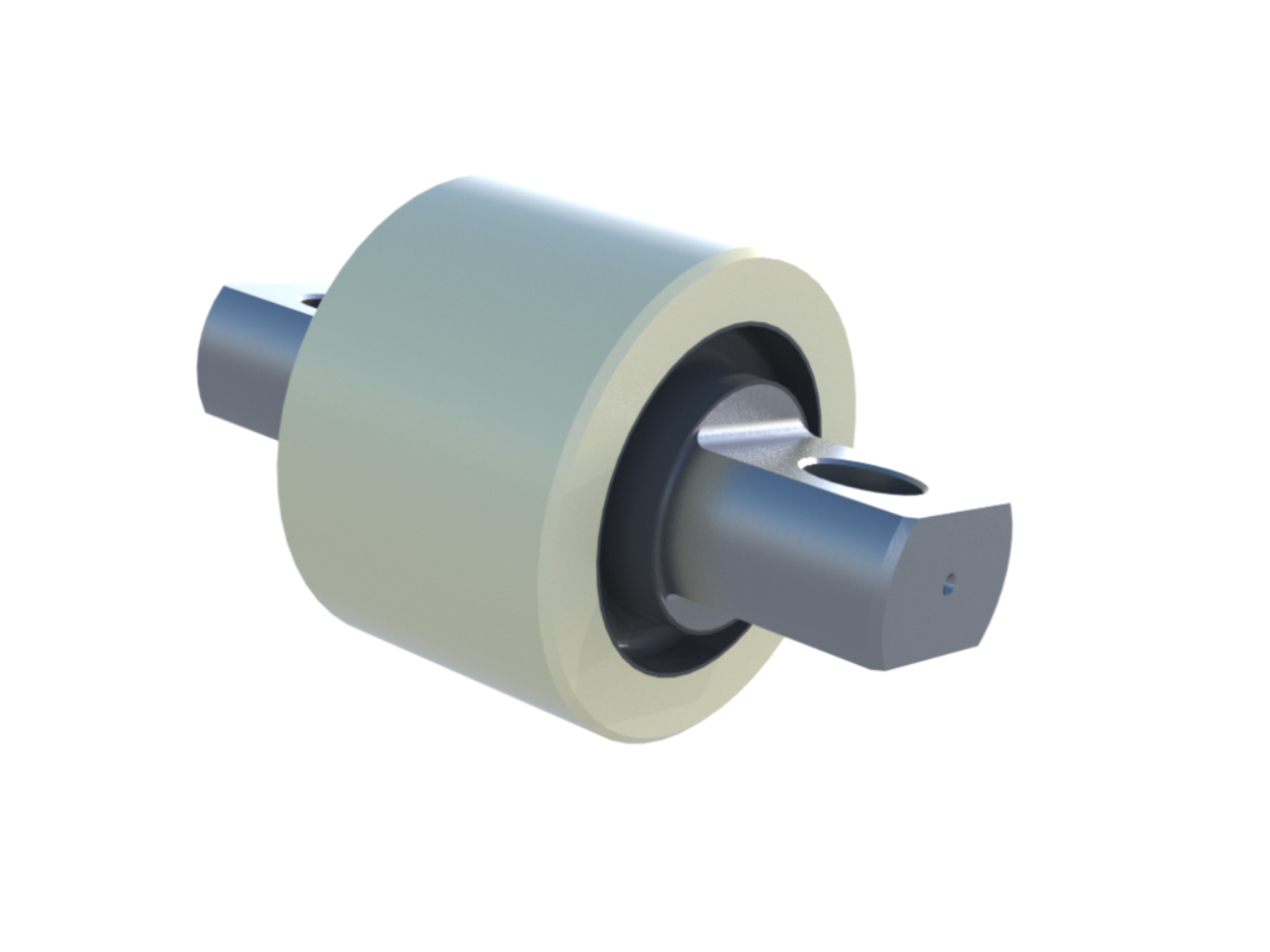

The motor suspension bush in a traction motor dampens and isolates vibrations, reducing noise and protecting other bogie components from wear and tear. It ensures proper alignment and stability of the motor, preventing excessive movement or misalignment. By minimizing stress and fatigue, it extends the lifespan of the motor and related components.

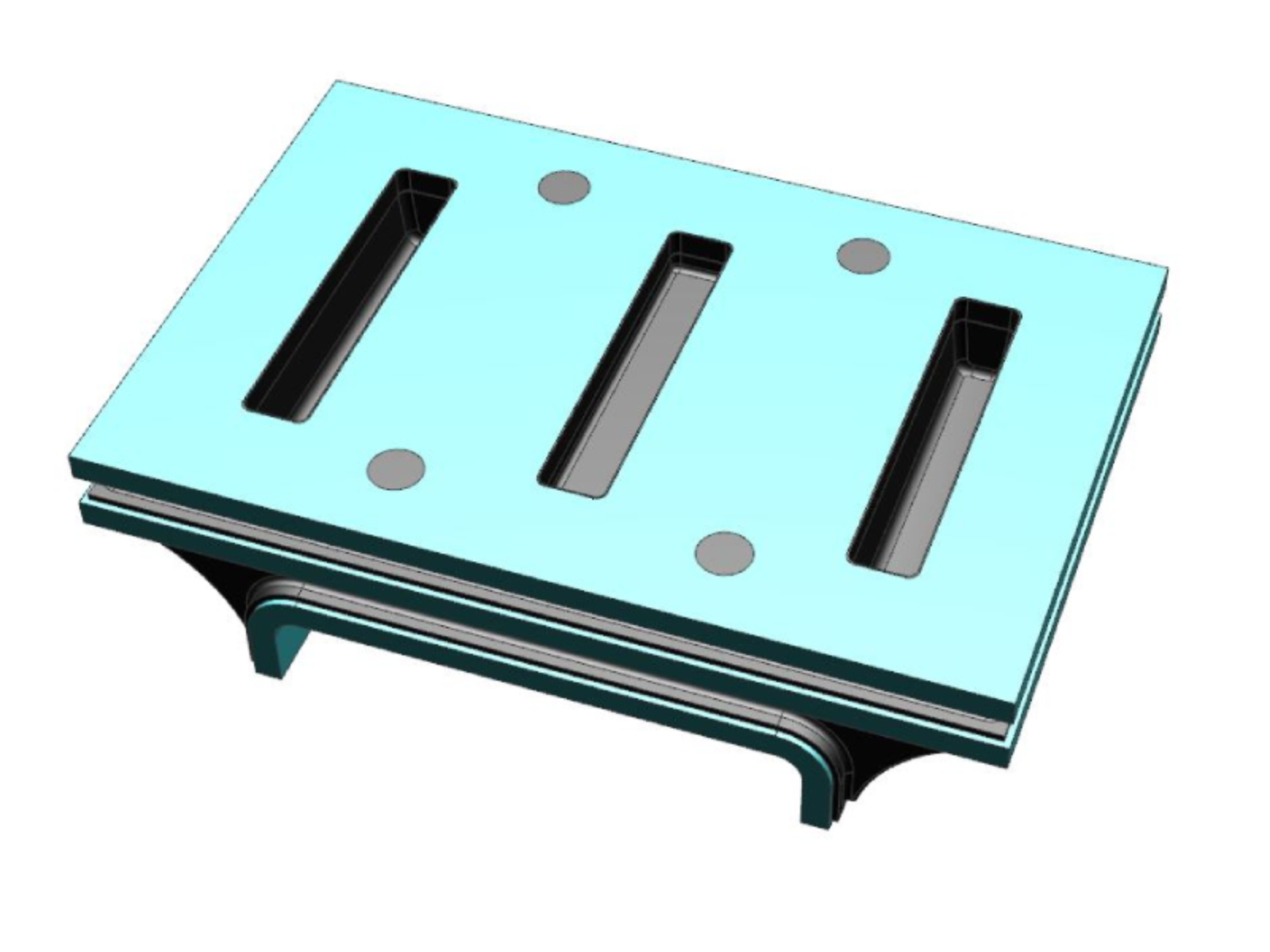

The motor suspension pad in a traction motor isolates vibrations, reducing noise and preventing their impact on other components, improving ride comfort. It absorbs shocks from track irregularities or abrupt movements, protecting the motor and bogie from damage. Additionally, it distributes loads evenly, reducing stress on components and enhancing their durability and lifespan.

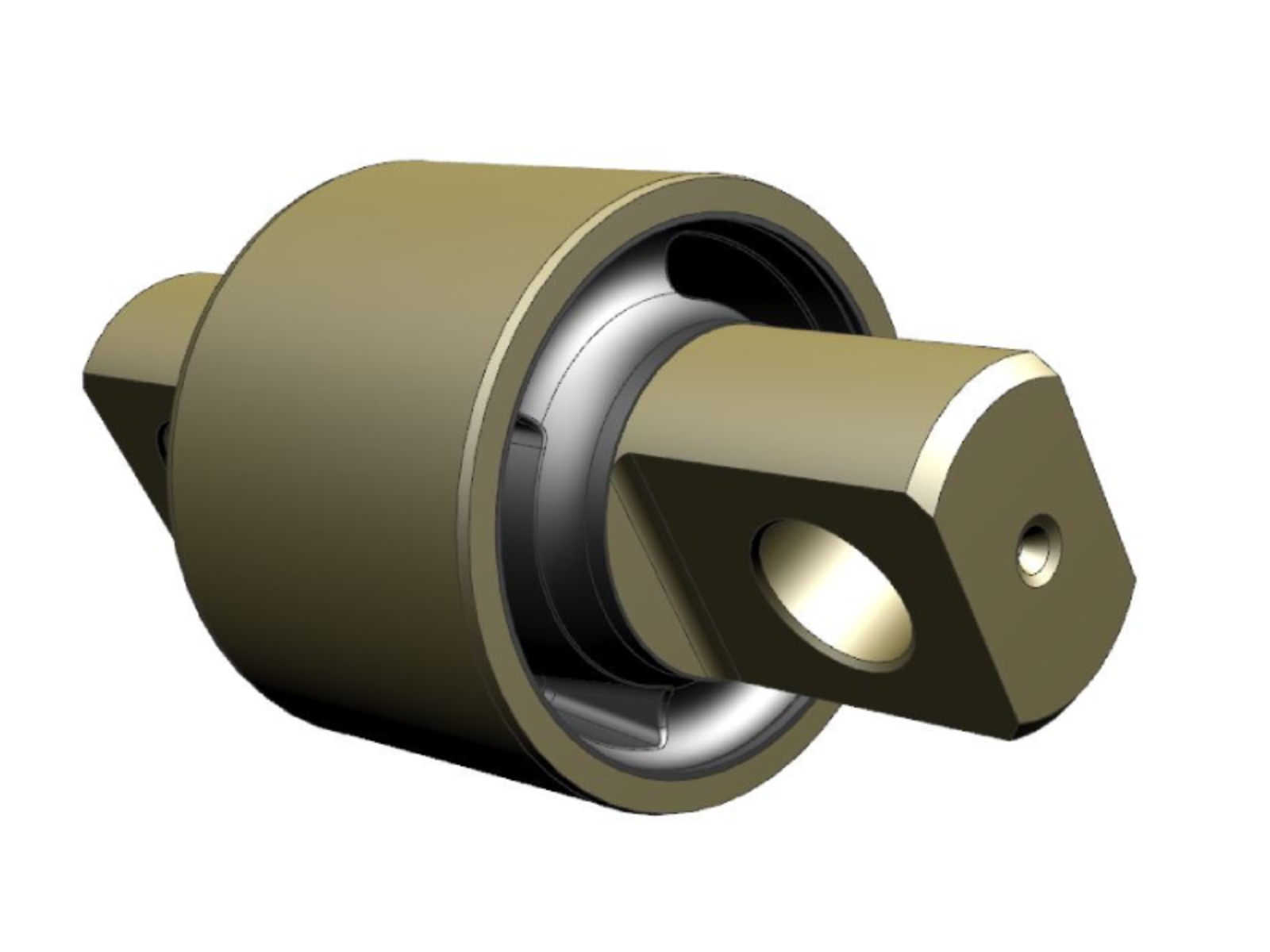

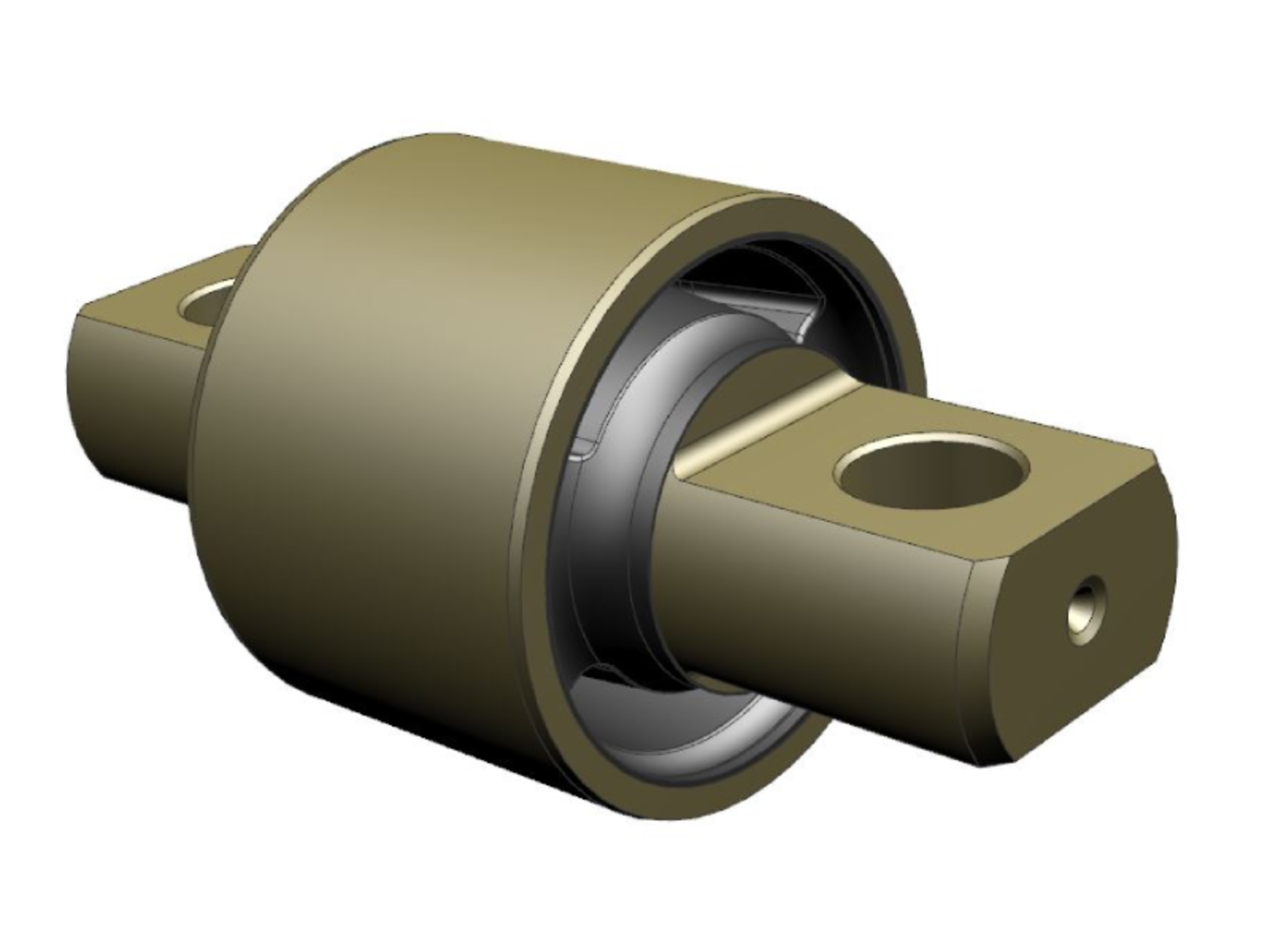

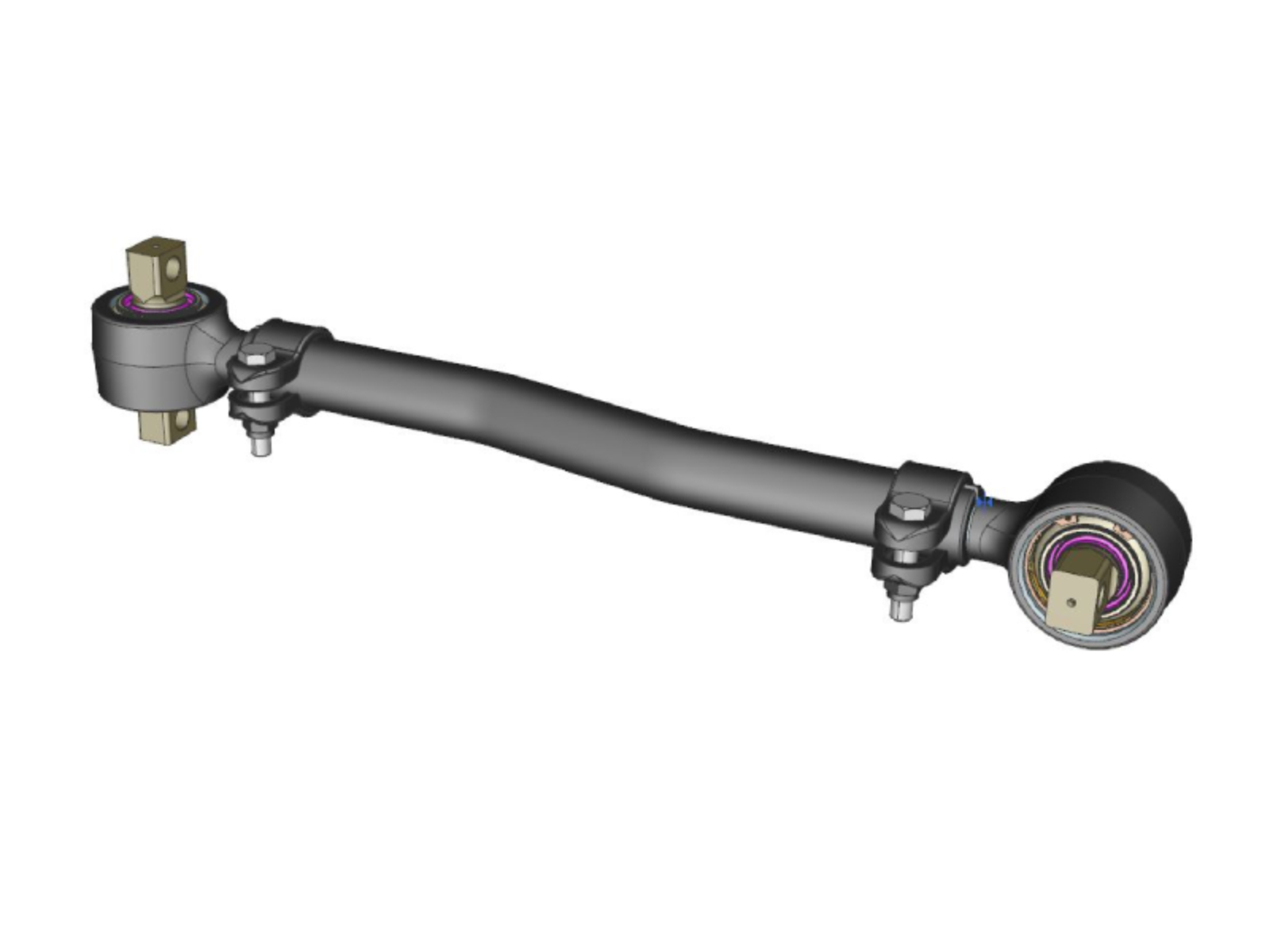

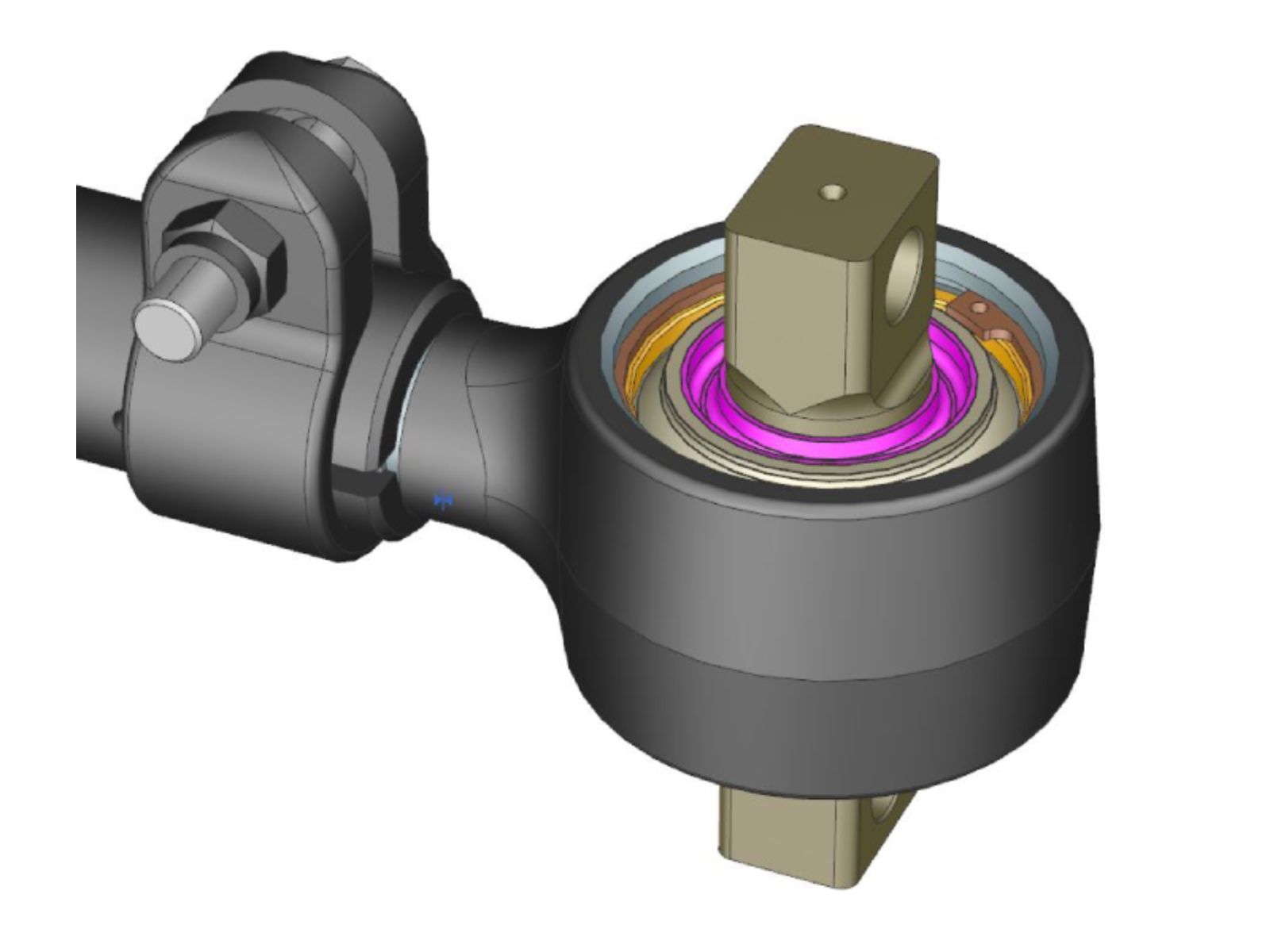

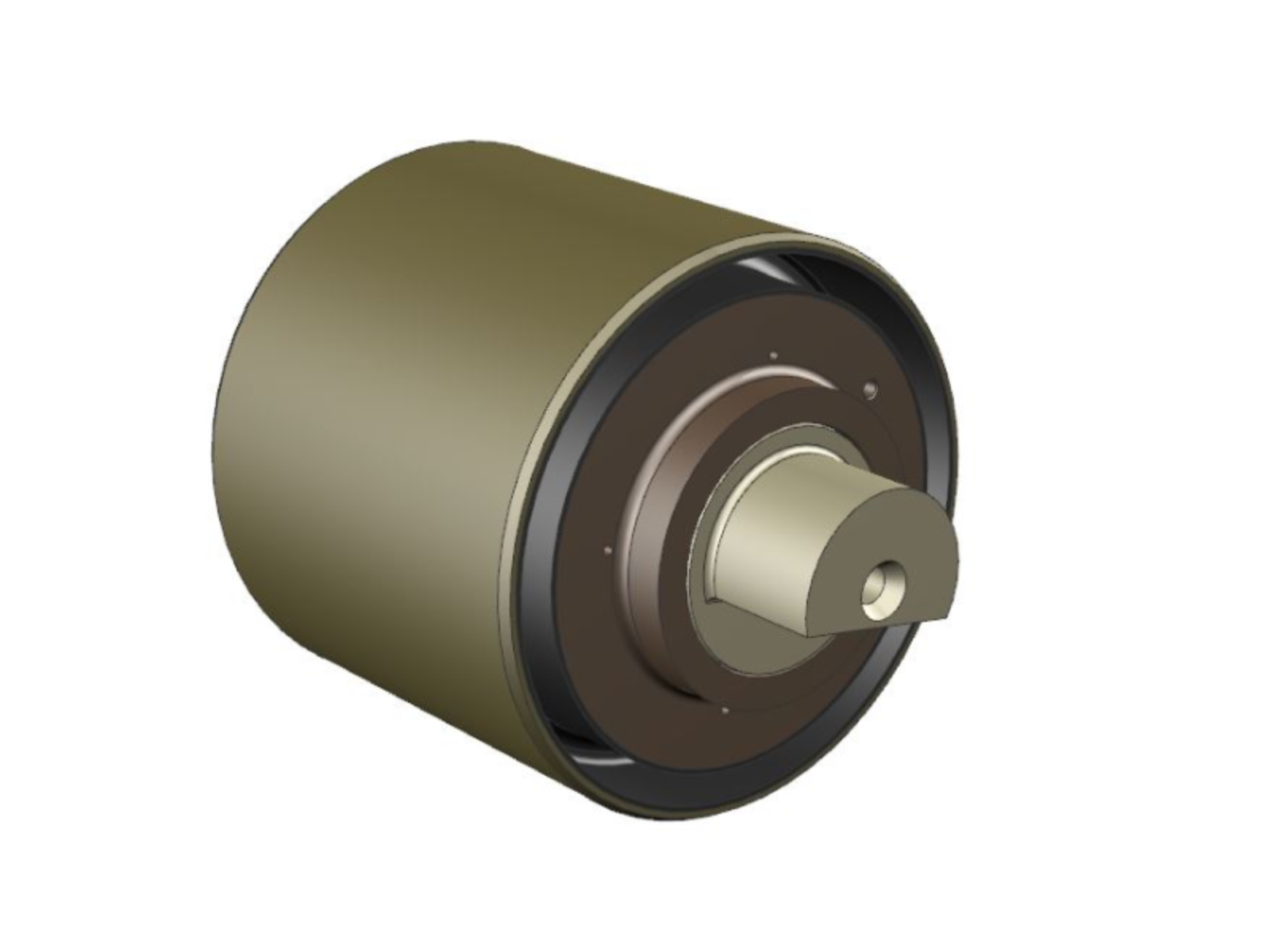

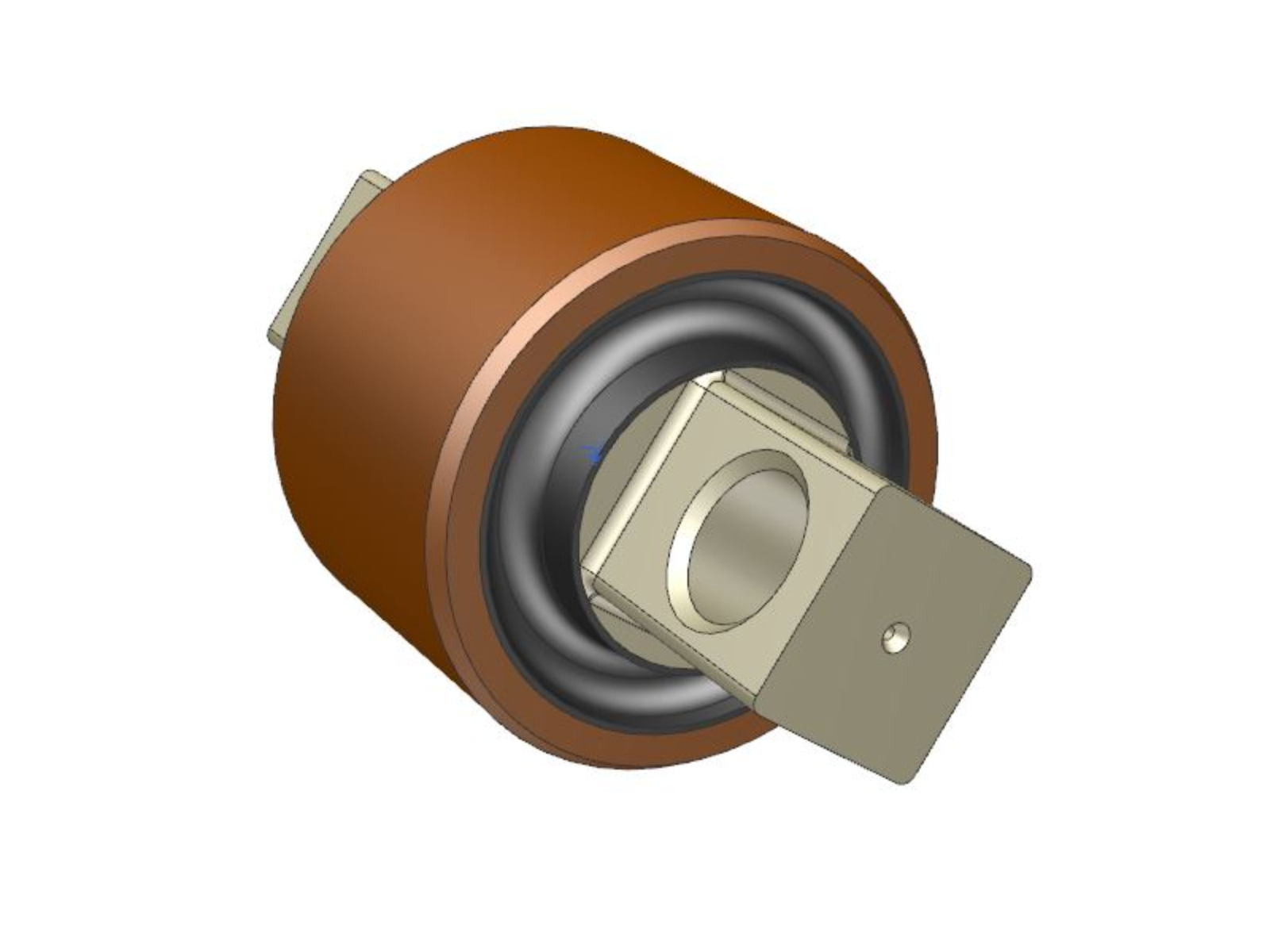

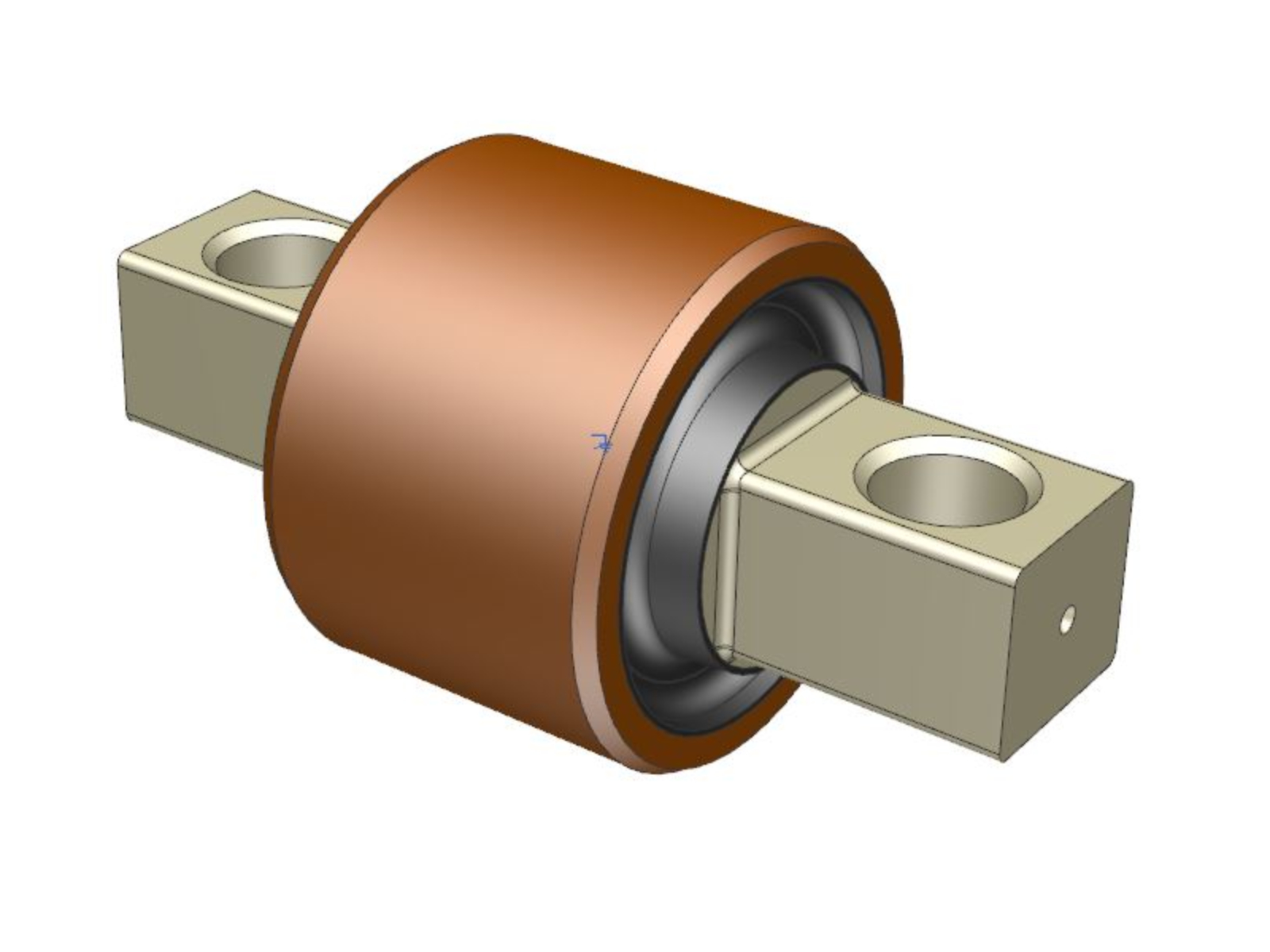

The traction rod assembly with a spherical bearing transmits traction and braking forces between the bogie and wheelsets, enabling propulsion and deceleration. The spherical bearing allows for articulation and misalignment, ensuring efficient power transfer while accommodating track variations and curves. It enhances stability, reduces stress on components, and improves ride quality by maintaining proper alignment and minimizing wear.

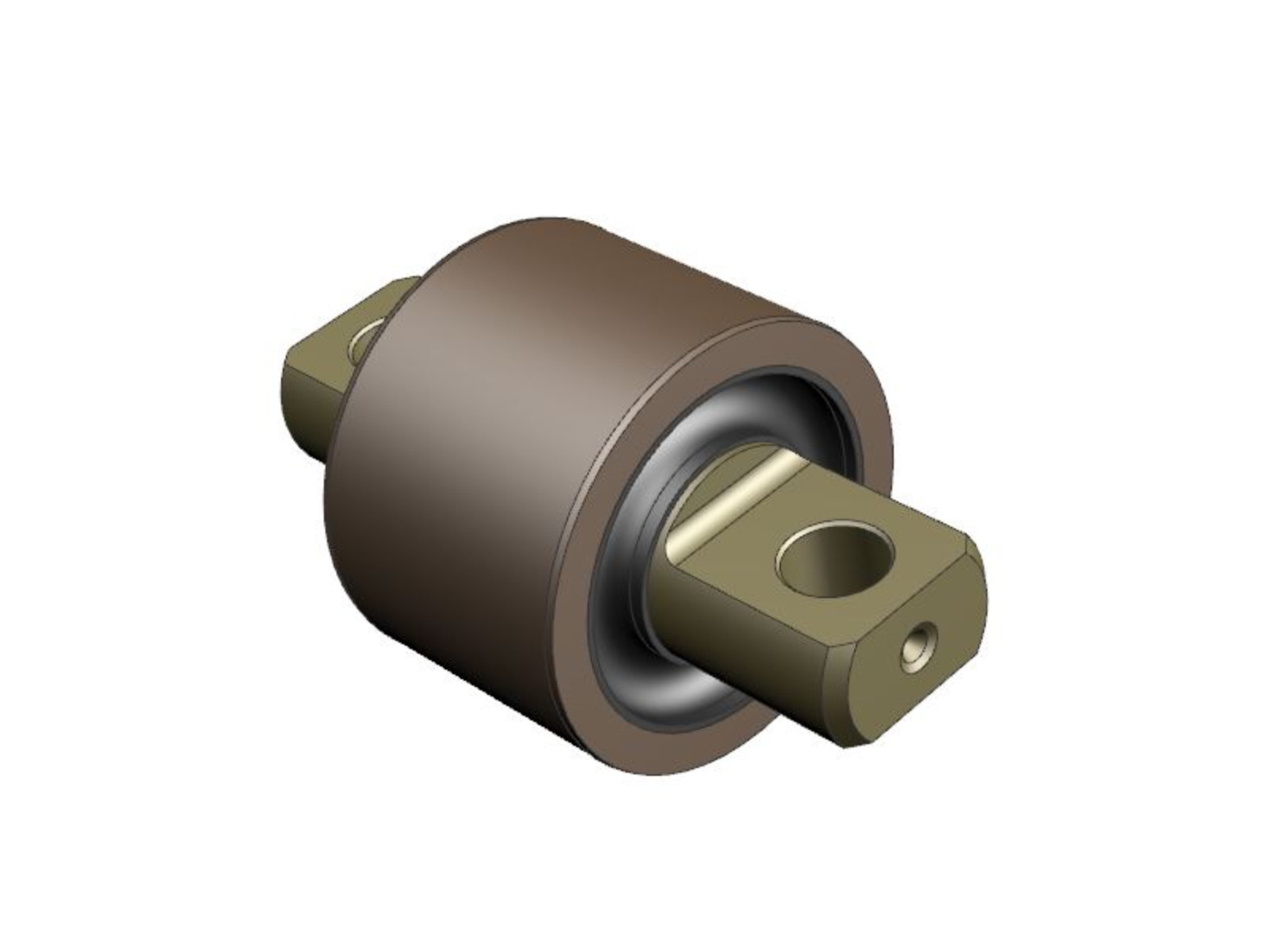

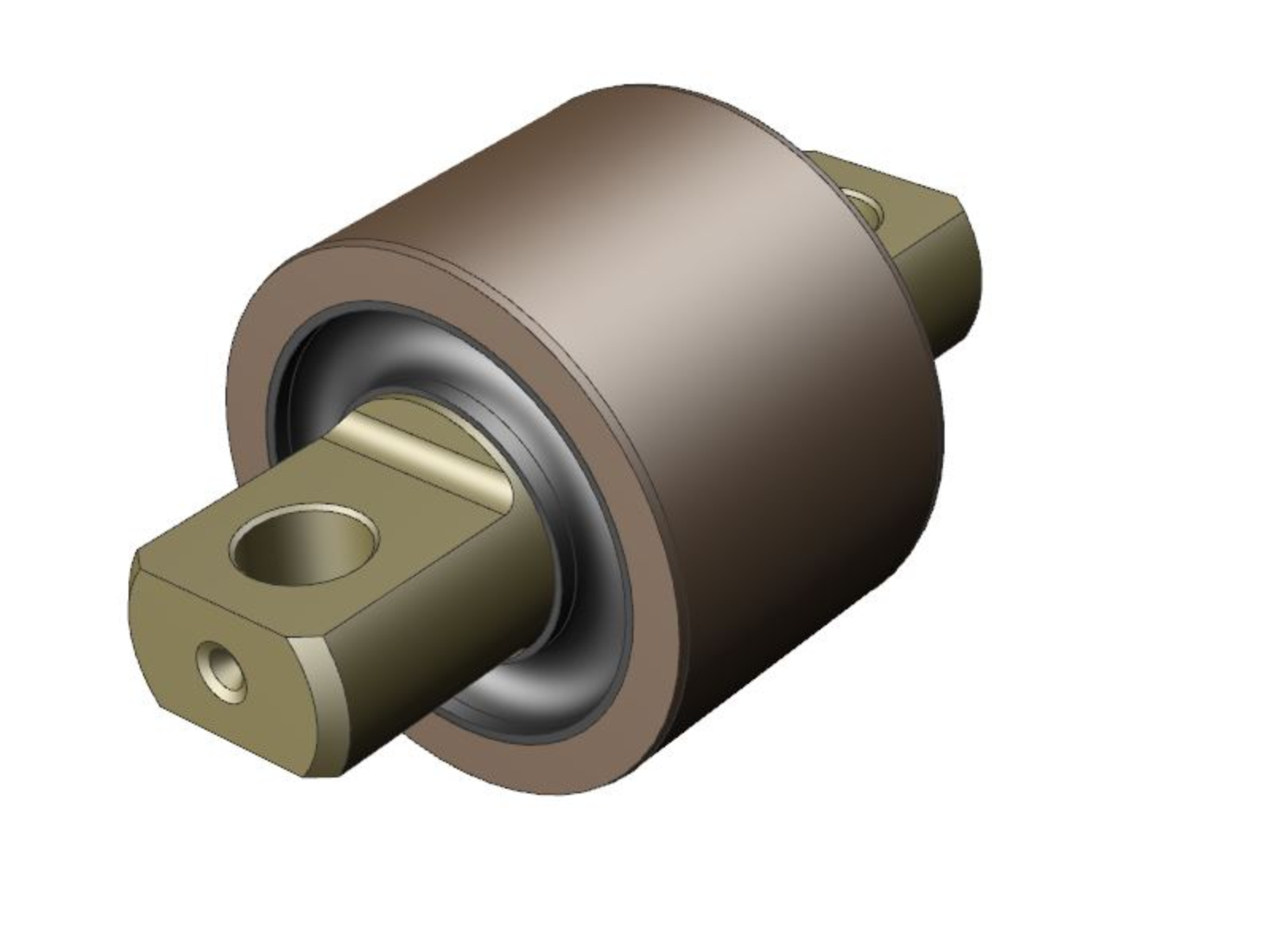

In the WAP7/WAG9 electric locomotive, spheriblocs are used to provide longitudinal guidance for the axle box housing while allowing controlled lateral movement, ensuring smooth operation of the axle guide rods. They are also fitted at both ends of the torque arm to support the traction motor mounting plate and connect the traction motor support arm to the bogie frame and center transom mounting lug, ensuring stability and vibration damping.

Elastomeric pads in wagon bogies absorb and dissipate vibrations and shocks caused by track irregularities, providing a smoother ride and reducing noise from wheel-rail interaction. They distribute weight evenly across the bogie, minimizing wear on components and extending the lifespan of wheels and axles. Additionally, their flexibility accommodates misalignments and track variations, ensuring smooth navigation of curves and reducing maintenance costs by lowering wear and tear.

Our dedicated team specializes in product design, supported by advanced FEA facilities for precise simulations. We analyse the stiffness of rubber-to-metal bonded products, material strength, stress, strain, and durability predictions. Additionally, we conduct VA/VE (Value Analysis/Value Engineering) to optimize performance and cost-effectiveness.

Our cutting-edge rubber mixing facility features K4-91L Intermix (Indus Harburg Freudenberger), complemented by multiple high-capacity Kneaders. With a capacity exceeding internal requirement, we offer surplus capability for premium rubber compounding. Equipped with carbon silos, MB (Masterbatch) and FB (Final Batch) chemical feeders, a Poka-Yoke traceability system, and advanced process controls, our facility ensures unmatched consistency, superior quality, and high-performance compounds.

Our state-of-the-art testing facilities are equipped with modern machinery, including a 330kN UTM-Zwick for highly precise static load and stiffness measurements. Additionally, we feature multiple durability and endurance testing machines, capable of simulating real-world conditions with 4-axis, 3-axis, and 1-axis configurations, ensuring comprehensive product performance validation.

Our dedicated team specializes in in-house mould design and manufacturing, ensuring cost-effective solutions and faster development cycles. This capability allows us to deliver high-quality, precision-engineered moulds that accelerate product development timelines, providing significant value to our customers.

Our customers operate in extremely demanding environments. They look to Premier Seals for the technological innovations and smart solutions that will help them meet the challenges of today and tomorrow.