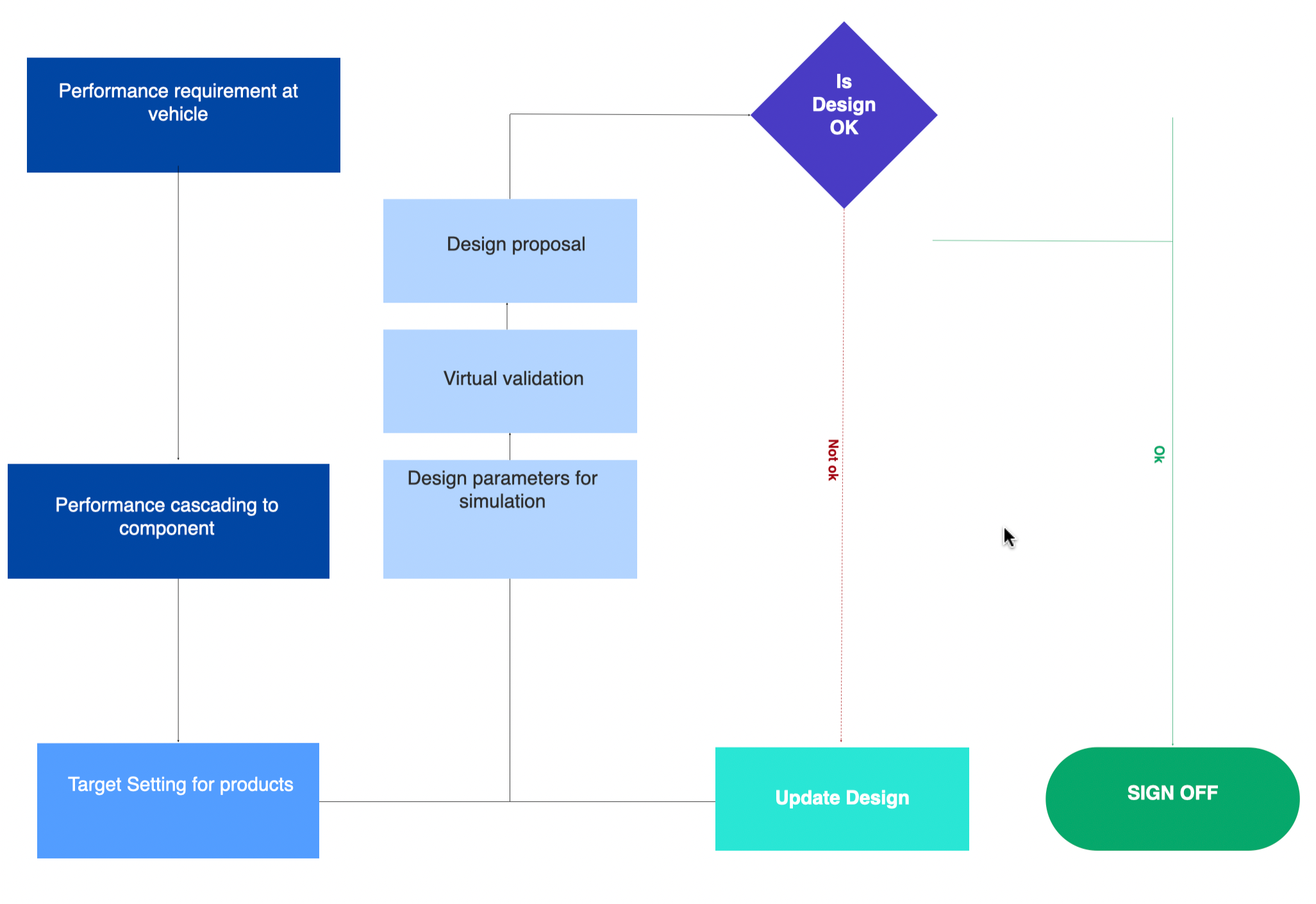

At Premier Group, We believe in achieving great things. One such hub ERIC is pushing us towards innovation. At the department of ERIC you can see the new now. We have a level of freedom that allows us to focus on our customers, and to combine the best from different worlds in order to develop practical solutions – a unique mixture of technological expertise, system calculation, system simulation, advanced engineering, future mobility and a hands-on mentality.

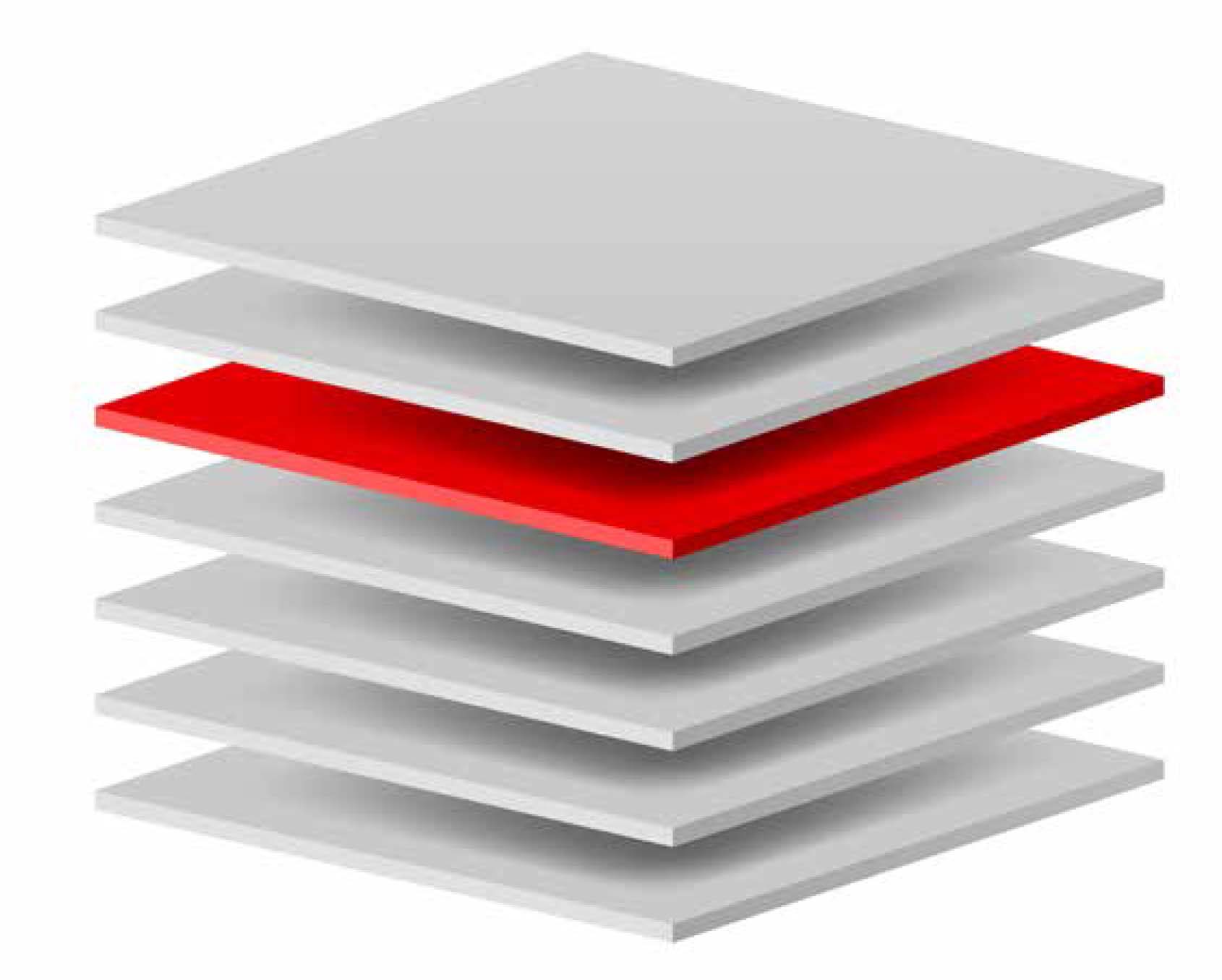

At Premier Group, no matter what NVH challenge we encounter, we have the right mix and match of the lightweight material. To achieve this, we have various VAVE which are as follows

Our success is achieved in different ways that include material substitution, gage thickness reduction, redesign of the part shape and size, elimination of redundant parts, and consolidation of several parts into one or two without sacrificing the overall structural integrity or functionality.

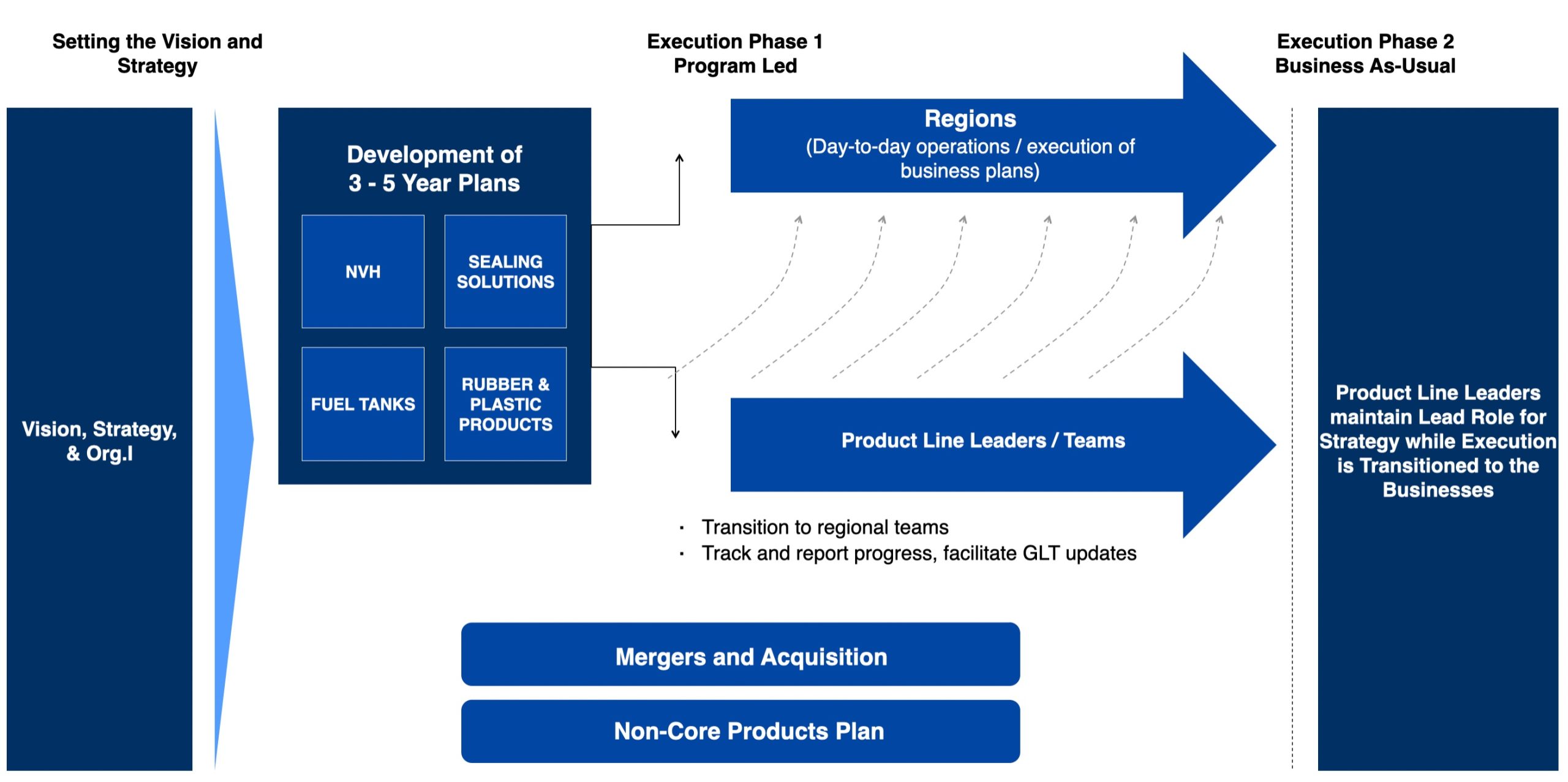

We will develops innovative products that will lead the market by always listening to customer’s voices.

We will satisfy the customer's needs by providing the high-quality product in the market.

We will lead the change of technology trend through constant efforts and solidify the foundation of future growth by securing and cultivating excellent talented persons.